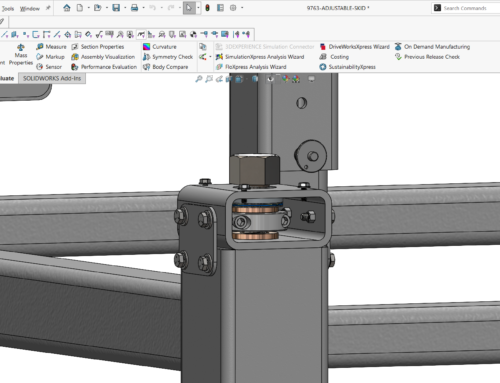

The next time you submit a project to a precision sheet metal fabrication shop, consider providing a 3D model instead of a 2D drawing.

While it’s possible to build a sheet metal part on modern equipment using only a 2D drawing, a 3D model speeds up the entire process, saving customers on cost and lead time while delivering a higher quality part.

At Ameritex, quality is always our number one goal, and that starts with having a good model. Whenever possible, we like to automate our processes so that they’re faster and less prone to human error. Detailed 3D models allow us to do exactly that.

4 Advantages of 3D Models for Precision Sheet Metal Fabrication

We know what you’re probably thinking: “It takes more time for me to make a 3D model!” You may be right, but any additional time or investment that you put in upfront pays off tenfold in these areas:

- Tooling. When engineers submit designs, they have no way of knowing what equipment the shop will use to build their parts. In other words, they’re inevitably making assumptions about how the part will turn out. Since sheet metal parts are first cut flat and then bent or folded into shape, dimensions change during bending and folding. If we receive a 2D print with a flat pattern and the tooling stretches the part differently than the engineer anticipated, it can affect tolerances. With a 3D model, we can work backward from the end result to nail those tight tolerances every single time.

- Assembly. When we’re assembling components, it’s important for us to see all the individual features to know exactly how the parts should fit together to function properly. The problem with a 2D print is that it only shows the outside of the assembly but not the inner dimensions! A 3D version allows us to see inside each component and verify specifications so that we know exactly what we’re working with.

- Accuracy. One of the most common issues we encounter with 2D design files is a mismatch between drawing and text. For example, the drawing may show that a hole is 2”, but the text reads 2.5”. This kind of discrepancy halts the entire process until we can get the engineer on the phone to clarify the intended dimensions. And every second is precious when you’re working on short lead times with urgent deadlines. 3D modeling has the advantage over 2D prints because it doesn’t allow for those kinds of inconsistencies. When we get your 3D model, we know that all dimensions will be aligned correctly.

- Quoting. Everyone loves a quick quote! The more information we have upfront, the faster we can quote your project. A 3D model provides significantly more information than a 2D print, allowing us to turn around your estimate and start working on your parts ASAP.

If you don’t have a 3D model for your part, we can absolutely make one for you. But we always encourage customers to provide 3D models during the quoting process whenever possible.

Do you need sheet metal fabrication services for your next project? Every job is important to us at Ameritex. Give us a shot, and we’ll prove it!