SERVICES

CAPABILITIES

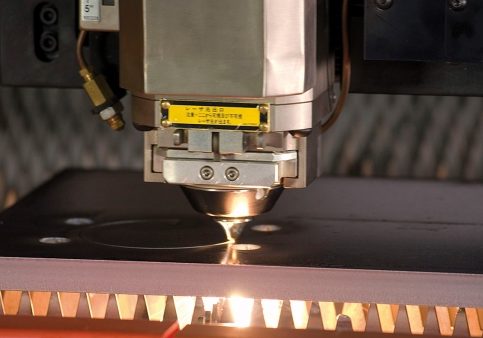

Sheet Laser Cutting

From 24ga to 1″ thick plate, you can count on us for fast and accurate laser cutting. Lead times as fast as same day!

LEARN MORE

Tube Laser Cutting

Fast and efficient cutting of angle, channel, tubing and pipe capable of processing complex designs with ease. Lead times as fast as same day!

LEARN MORE

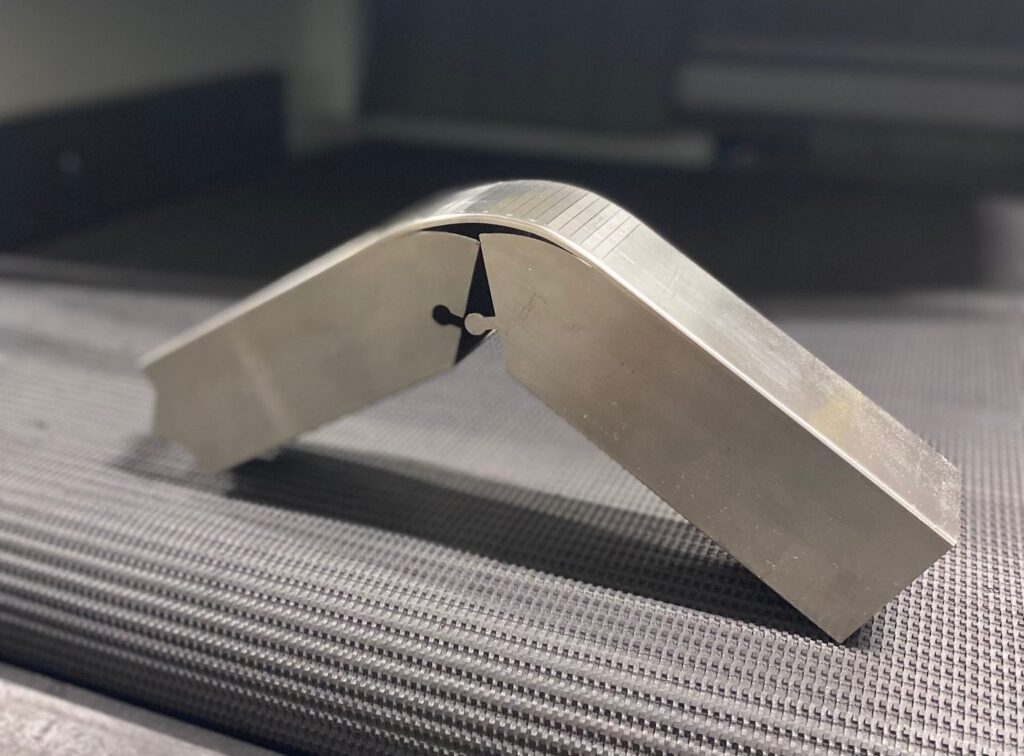

CNC Press Brake Forming

24ga to ½” plate formed with ease utilizing the latest in forming technology.

LEARN MORE

CNC Punching

Does your design have repetitive features or forming such as extrusions, countersinks, bridges, and tie downs? See what our punching services can do for you!

LEARN MORE

Saw Cutting

Are your parts too big for our tube laser? Our saw cutting services may be a better fit.

LEARN MORE

Sheet & Plate Rolling

Up to 6ft long or ½”, our plate rolling services can be used for a huge array of products.

LEARN MORE

CNC Machining

Sheet metal, plate, structural steel and machining under one roof? YES! Check out how our machining services can help you simplify your vendor list.

LEARN MORE

Hardware Insertion

We have the ability to insert or weld in hardware quickly and accurately with the latest hardware installation equipment.

LEARN MORE

Welding

We offer mig weld, pulse and tig welding services for carbon steel, aluminum and stainless steel.

LEARN MORE

Spot Welding

We offer spot welding services as an economical way of joining sheet metal parts and reliable method of attaching fasteners to sheet metal.

LEARN MORE

Finishing & Powder Coating

Explore the wide array of finishing available both in house and through our vast network of third-party finishers.

LEARN MORE

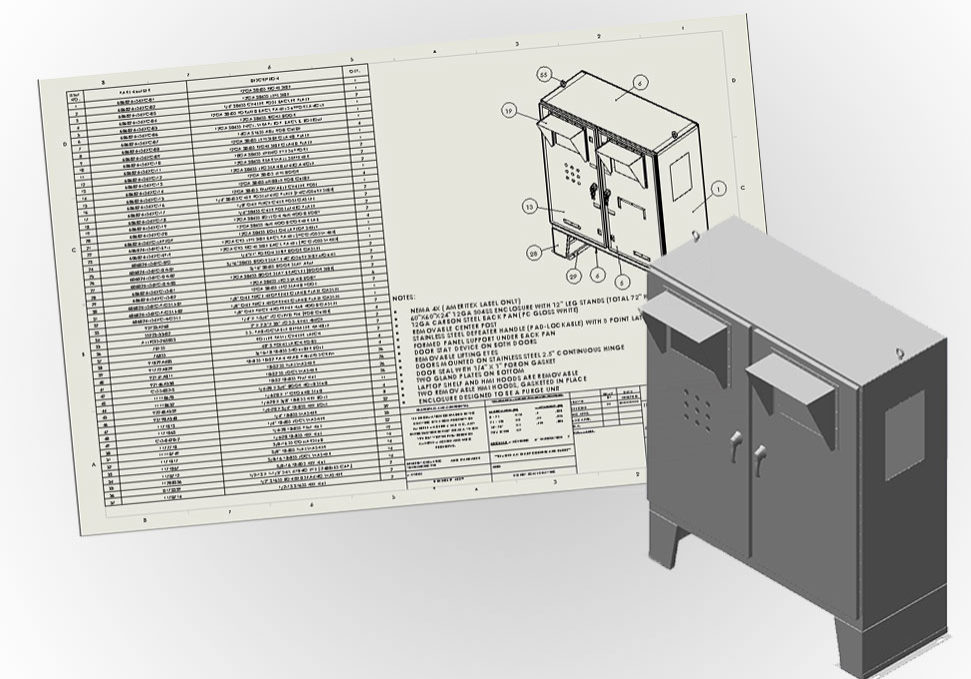

Design & Engineering

Discover the plethora of services we can offer outside the shop to ensure your product can be manufactured as designed at a fair price.

LEARN MORE