Copper fabrication and machining: yes, we do it!

Ameritex has worked with copper for as far back as we can remember. But many customers don’t realize we provide copper fabrication and machining services until they take a shop tour and see the copper projects we’re working on.

It’s time to demystify one of our best-kept secrets with a little show and tell. First, we’ll tell you what makes us a great copper machining and fabrication partner. Then, we’ll show you some of our favorite sample parts made from everyone’s favorite electrically conductive material.

Copper Fabrication and Machining for Electrical Applications

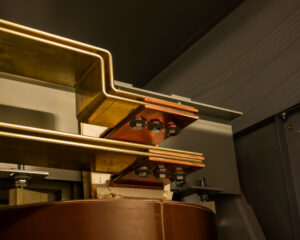

Thanks to its high thermal and electrical conductivity, copper is popular for electrical applications like busbars and contactors. Many integrator customers have come to rely onAmeritex to create and mount copper busbars into the enclosures we fabricate for them. This solution prevents them from having to purchase copper bars and drill the holes themselves.

We’re always open to taking on new copper machining and fabrication projects. Here’s a quick look at what you can expect from us:

1. In-house fabrication and machining capabilities

Many copper parts require a combination of sheet metal fabrication and CNC machining capabilities. Yet it can be difficult to find a shop that offers both capabilities in-house.

Through the use of our saws, punch presses, fiber lasers, CNC machines, and press brakes, Ameritex has the unique capability to manufacture virtually any copper part that comes our way.

2. Latest and greatest equipment

Older CO2 lasers typically can’t cut through copper effectively. It’s one of the many limitations of the outdated CO2 technology.

At Ameritex, we make it a point to invest in the newest and most advanced technology. Our high-powered fiber laser is ideally suited for cutting copper.

3. Excellent plating vendors

Copper corrodes easily, and the corrosion can inhibit its conductivity. Many copper parts receive a tin or nickel coating to prevent corrosion.

Ameritex has close relationships with excellent tin and nickel plating vendors who can provide critical plating services quickly and reliably.

4. Expertise you can trust

Copper is generally easy to cut, but it’s expensive. Many shops avoid it for that reason, unwilling to take on the risk of replacing such a costly material in the event that they need to start over on a project.

At Ameritex, we’re fully confident in our copper machining and fabrication expertise. We willingly accept copper projects because we know we can get the job done right.

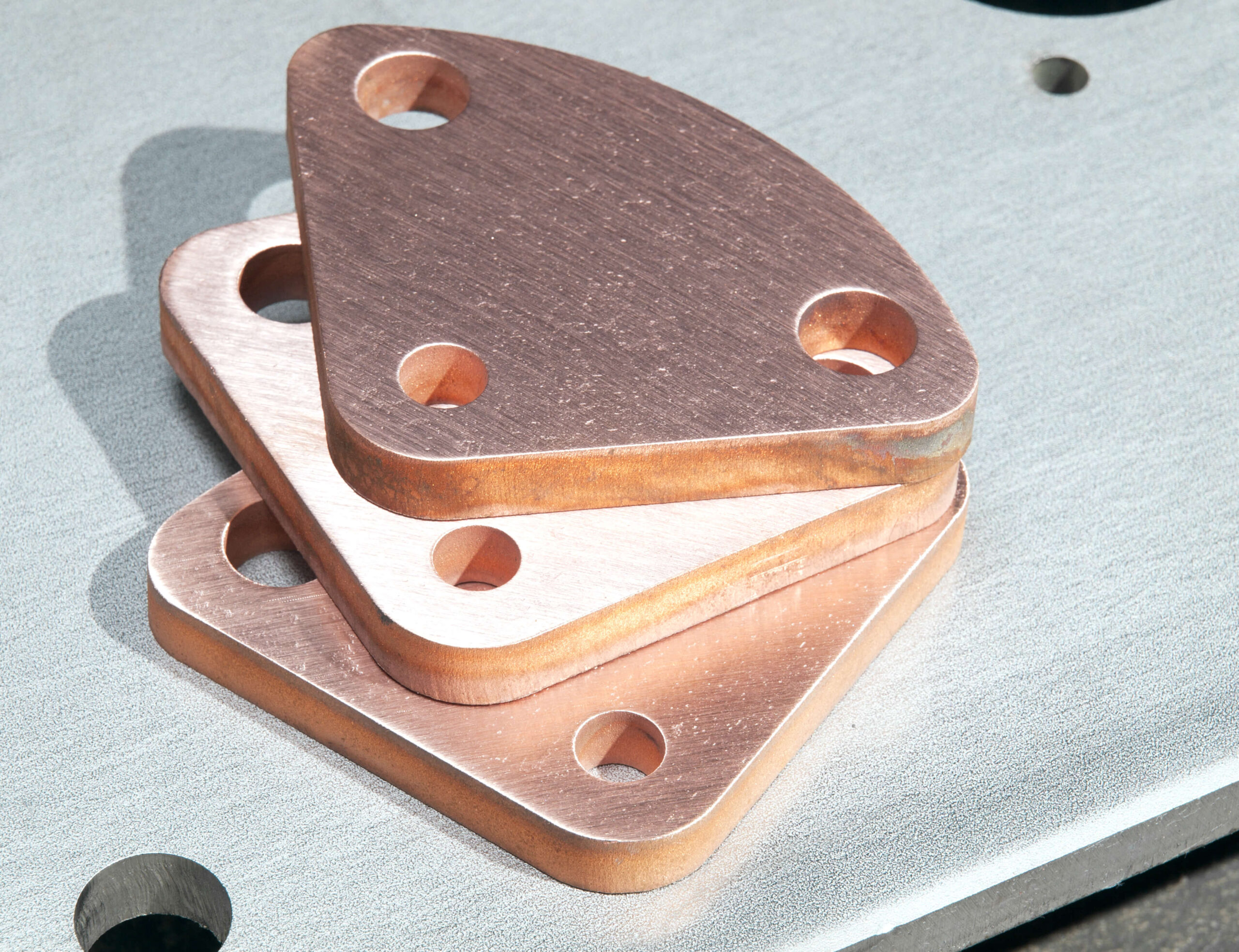

Samples of Our Copper Machining and Fabrication Work

Busbar applications are typically simple, but some copper parts are complex and may even require custom tooling. No matter the copper parts you need, Ameritex is here to help. Check out these samples of our work and give us a shot!