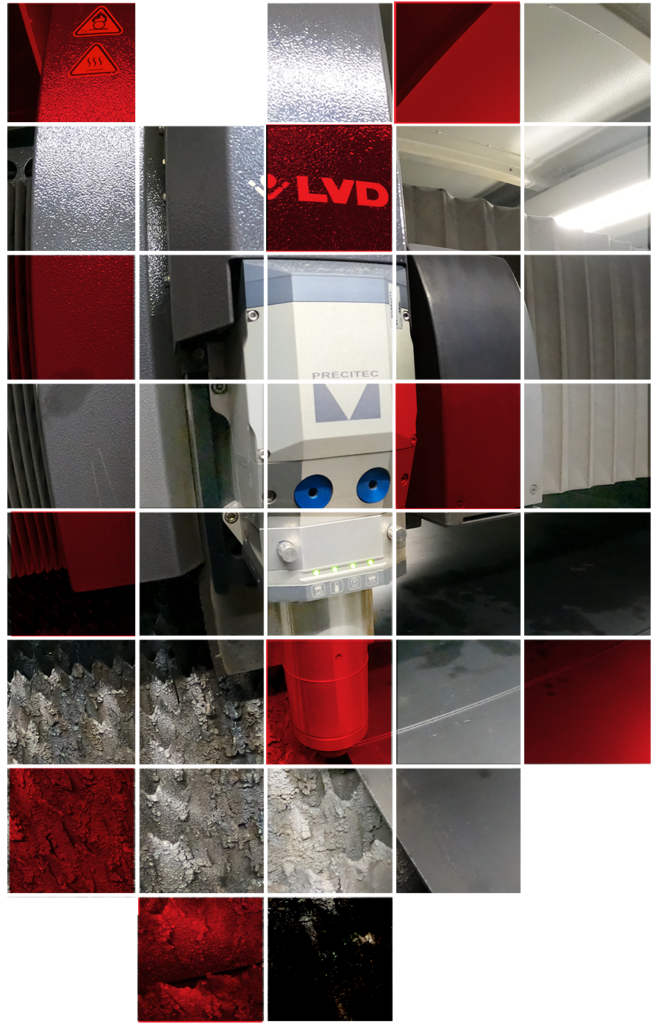

Laser Cutting

Laser cutting is a crucial process in the metal fabrication industry. At Ameritex, we take pride in our commitment to stay at the forefront of technological advancement. This technology is developing quickly, and current cutting technologies being used are quickly out of date. Ameritex, ensures we stay at the “cutting edge” by continuously investing in upgrading. We embrace the latest power, automation, and laser cutting technologies. Currently we have 2 sheet laser cutters with a combined 72 shelves for material handling, allowing us to load close to 500,000lbs of material to be loaded and unloaded automatically. Our tower shelves allow unsurpassed levels of automation giving us the capabilities to cut around the clock.

Our lasers utilize a 10kw and 20kw power source capable of cutting from .01” up to 1.5” thick plate with ease. Moreover by utilizing fiber cutting technology, we can also cut copper, nickel, brass, and an array of exotic materials that older CO2 technology cannot cut. Furthermore, using these systems we can handle sheet sizes up to 78X157” (2X4M) with ease.

Explore our blog for more in-depth insights into our cutting capabilities and how we utilize this advanced technology to meet diverse project requirements. If you have project in mind, don’t hesitate to reach out to us for a quote.

Do you have a laser-cutting project you need help with? Reach out for a quote today!