Ameritex’s journey to implementing lean manufacturing practices at our precision sheet metal fabrication shop continues, and we’re thrilled to announce the latest development:

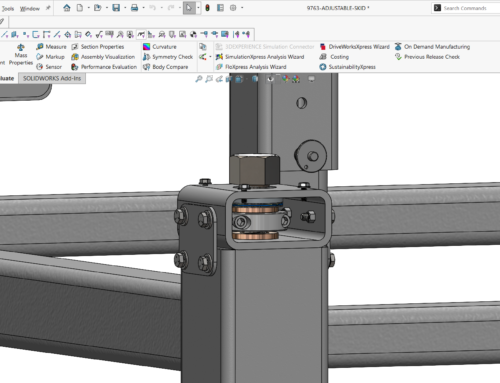

Through our work with the BeehiveFund, we applied flexible assembly lines to our shop processes that we now refer to as “Flexlines”.

What Are FlexLines and How Does the Process Work?

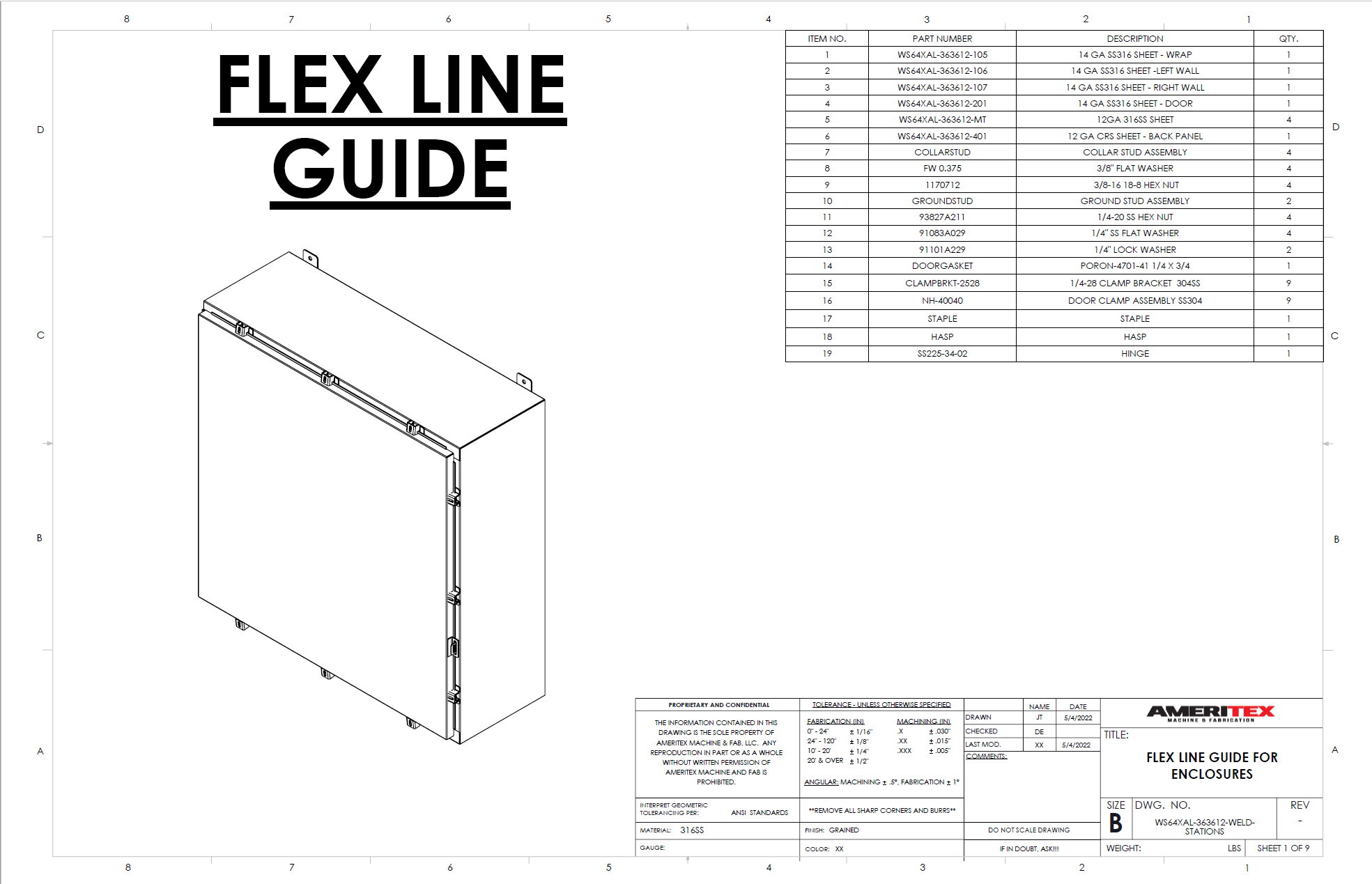

FlexLines are flexible fabrication lines we’ve established to make custom fabrications in a rapid and controlled manner. The goal is to break down each project into small, quick, and manageable steps so that multiple fabricators can work on an assembly, performing designated tasks in sequential order.

Up until now, we’ve dedicated FlexLines to relatively high-volume products, but in the next couple of months, we plan to use the same process for low-volume work as well. We expect this development to drastically improve the throughput of our precision sheet metal fabrication shop.

Here’s how the process works:

- We increased our engineering staff to thoroughly plan out and break down projects into well-balanced steps that fit the fabrication line. When a project kicks off, an engineer meets with the production manager and line supervisor to discuss all the necessary steps and determine what resources are needed from various departments to feed the line.

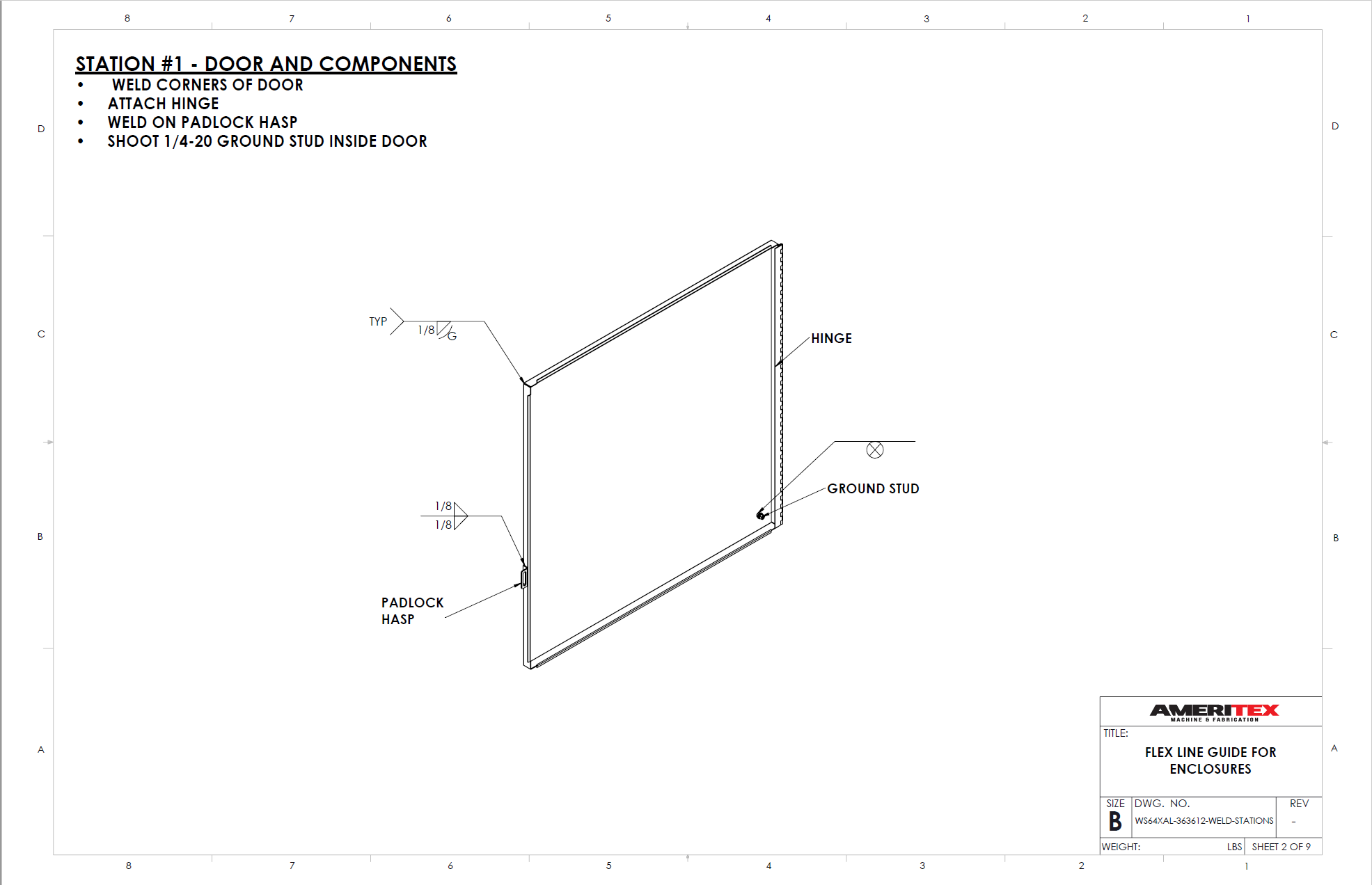

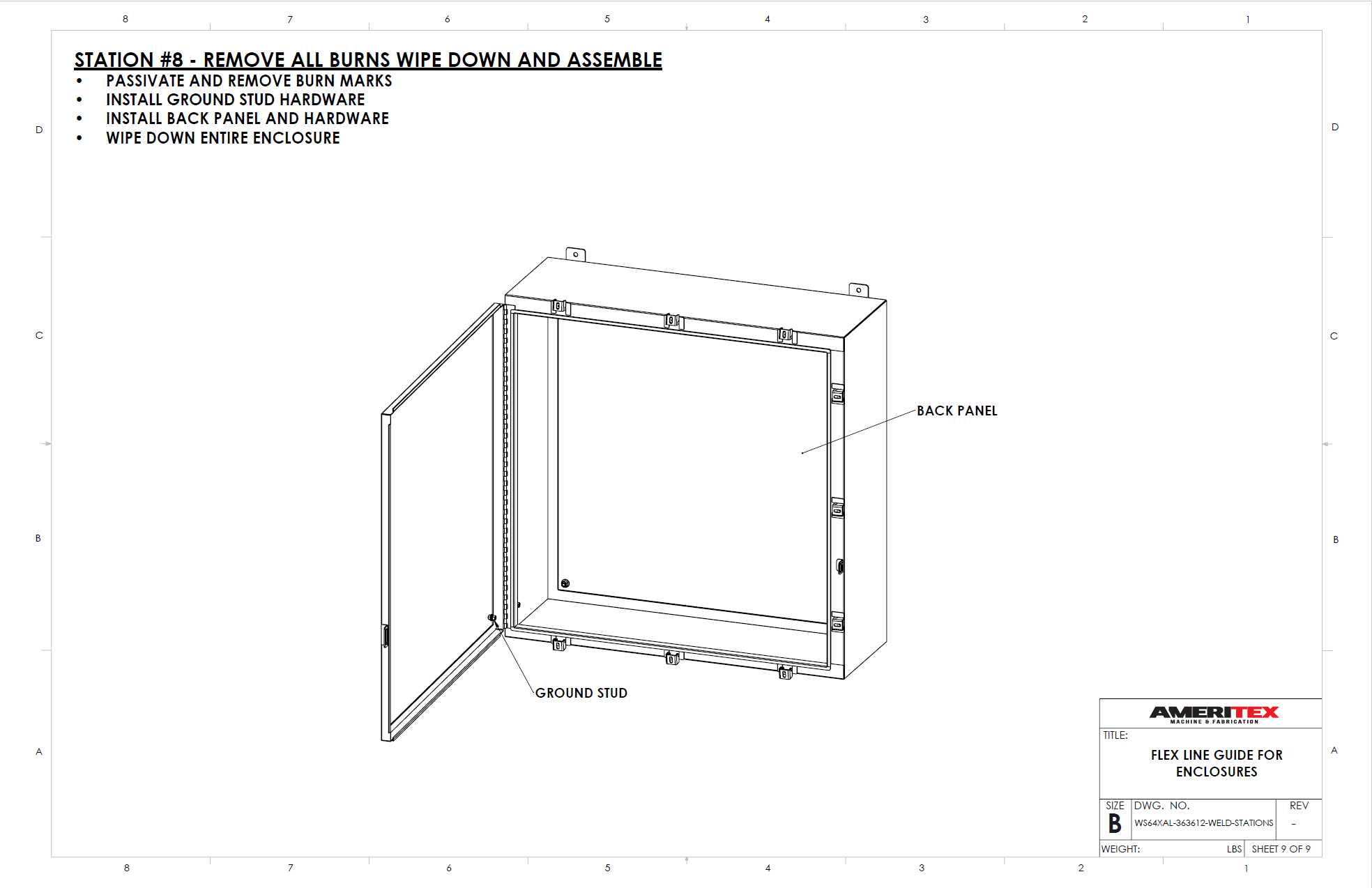

- Each step is transferred to a visual work instruction card so that fabricators can see exactly what needs to be done at their designated workstations. The cards are stored for repeat orders, and we’re currently creating standard cards for the products we most commonly build (e.g., structural fabricated racks, sheet metal fabricated enclosures).

- Once the job hits the line, fabricators in teams of 7-10—each following the instruction card at their workstation—focus exclusively on one project to complete it as quickly as possible. Each work station has the tools it needs to complete its required tasks and a rolling cart to easily move the workpiece from one station to the next.

- The fabricator at each workstation conducts a brief quality check to inspect the previous station’s work before beginning their portion of the job. This extra step ensures that any quality defects are detected and remedied ASAP—well before the product reaches the end of the line.

- When the product exits the line, a quality control specialist conducts a final QC check, approving each product for shipment or notifying the line of any corrections that need to be made.

Depending on the scale of the job, a typical line will produce its first assembly in as little as 1-3hrs, with the following assemblies being completed every 10-30 minutes after that. By balancing our lines, we can have consistent production from the line from project to project and decrease the amount of time individual jobs spend on the shop floor.

When a project is finished, the work instruction cards are swapped out with cards for the next job, and the workstations are cleaned and prepped accordingly.

Why FlexLines Are So Effective

Here are a few of the ways FlexLines make our business more effective and efficient:

Growing with our customers

It’s no secret that the manufacturing industry continues to face significant labor challenges. While highly skilled fabricators used to be knowledgeable in every step of an assembly process, the skills gap has made it incredibly difficult to find such well-rounded employees in today’s labor pool.

For shops to successfully grow along with their customers, they must be willing to think outside the box and develop creative new ways to scale internally.

FlexLines allow us to use our internal resources more effectively. Our highly skilled employees—engineers, production managers, line supervisors, and veteran fabricators—handle the strategic thinking for each project, and the fabricators on the assembly line focus on the capabilities they specialize in (e.g., welding, grinding, polishing and assembly).

Optimizing quality and lead times

FlexLines will enable us to turn around projects more quickly. With each assembly planned out in advance, there’s less idle time on the shop floor. Fabricators enter a workstation with everything they need to do laid out clearly in front of them so they can get to work quickly and easily.

The process is also advantageous from a quality standpoint. Each fabricator has the opportunity to truly master a small portion of the job instead of being responsible for the entire scope of the project. Plus, breaking down each part of the assembly process into clear steps with checkpoints for quality inspection allows us to proactively catch and address issues as they occur.

When you have a large sheet metal or structural fabrication project, you can count on Ameritex to scale up and deliver a high-quality product. We manage this whole process internally, so there is no need to request FlexLines on your RFQ. We just like providing transparency into how we do business so you feel confident working with us. Request a quote today!