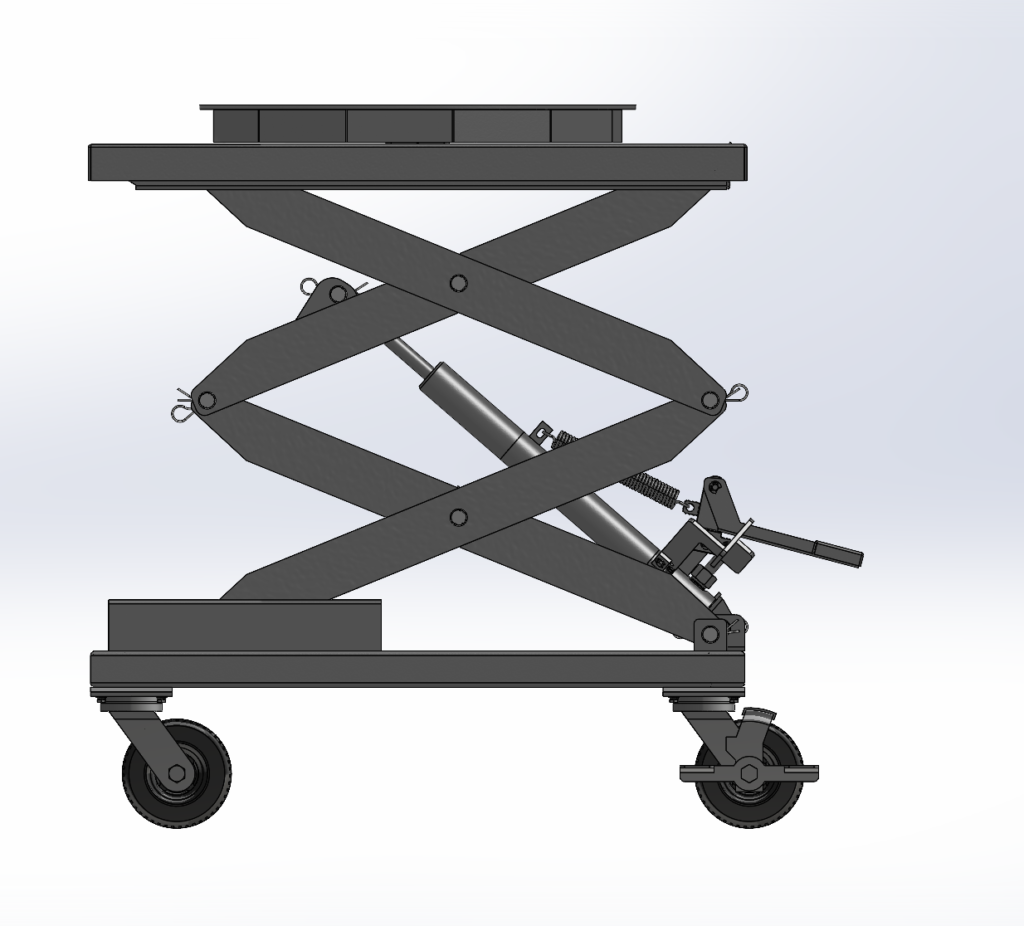

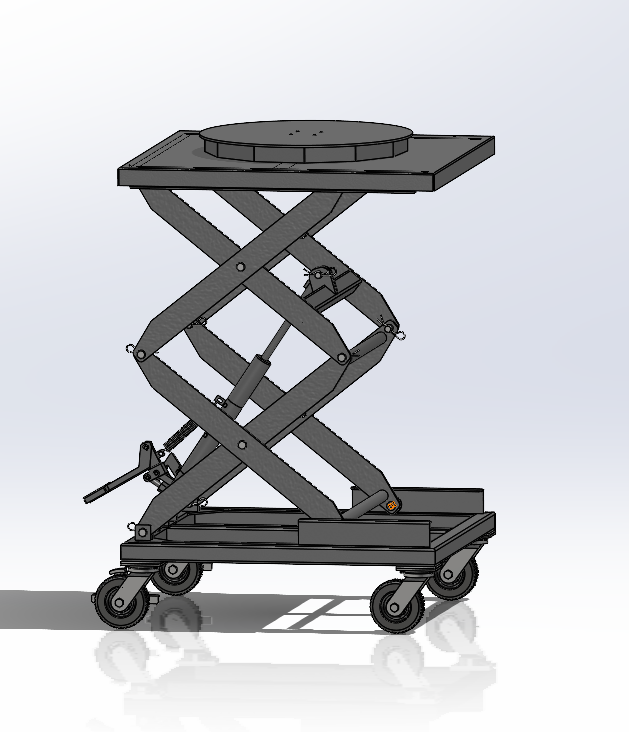

When Ameritex needed a scissor-lift cart to feed materials into our press brake, the off-the-shelf products we tried didn’t fit the bill. We wanted a cart with turntables that would allow us to rotate parts easily. So we took matters into our own hands, leveraging our expertise in tube laser cutting services and sheet metal assembly to create a custom solution.

Now, we’re pleased to offer this unique service to customers who share our frustration with off-the-shelf material carts (e.g., pallet carts, rolling carts, scissor-lift carts) and are in search of their own custom solutions. Off the shelf carts may be over or under built (weight capacity), the incorrect size (Length, width and height) or maybe missing features that would optimize your process (like the turntable on our press brake carts).

Whether you need light weight aluminum carts for simple warehouse picking or heavy duty pallet trucks to move heavy items as we do on our floor the custom solution is just a phone call away.

Material Handling Solutions Support Industrial Automation

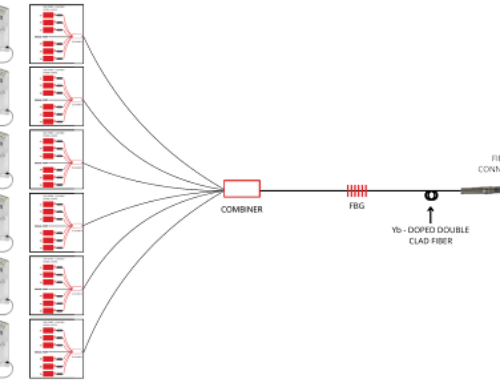

On top of hand trucks and other manual material handling solutions many of our customers who benefit the most from the way we manufacture sheet metal and structural steel assemblies are harnessing the power of industrial automation. As labor costs rise and skilled labor becomes harder to find, nearly all repeatable processes are being automated.

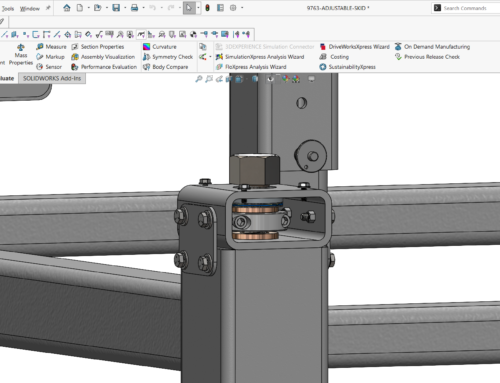

Most of these custom fabrications are made from laser cut structural steel with bolt holes and wireways cut throughout that support the integration of chains, motors and conveyors.

Ameritex has the skills and expertise to create custom material handling solutions to support our customers’ automation projects.

Special Considerations for Material Handling Solutions

Here’s a look at the special considerations that inform these sheet metal assemblies:

Ergonomic design

Our material handling carts are designed to bring the workpiece up to a height or position that causes less strain on the worker. Adjustable-height scissor-lift carts like the one we made for our press brake accomplish this goal.

The carts are incredibly durable, fabricated for 10 gauge, ¼” and ⅜” steel with four 1,000-pound capacity caster wheels. The tops rotate so that the worker can spin parts around with ease.

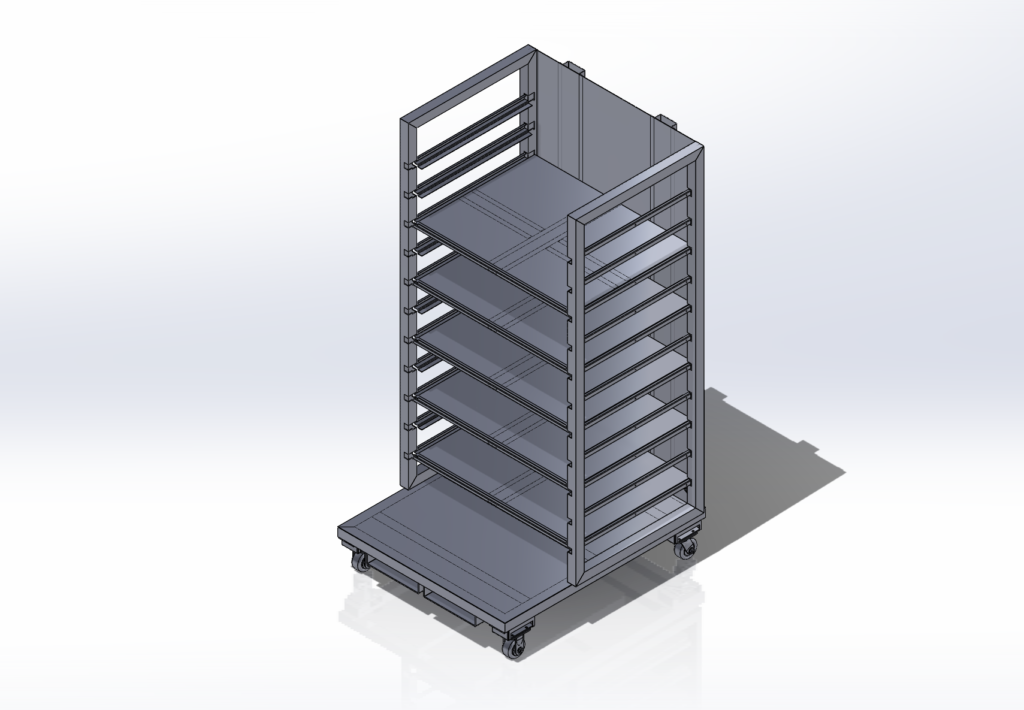

Reduced footprint

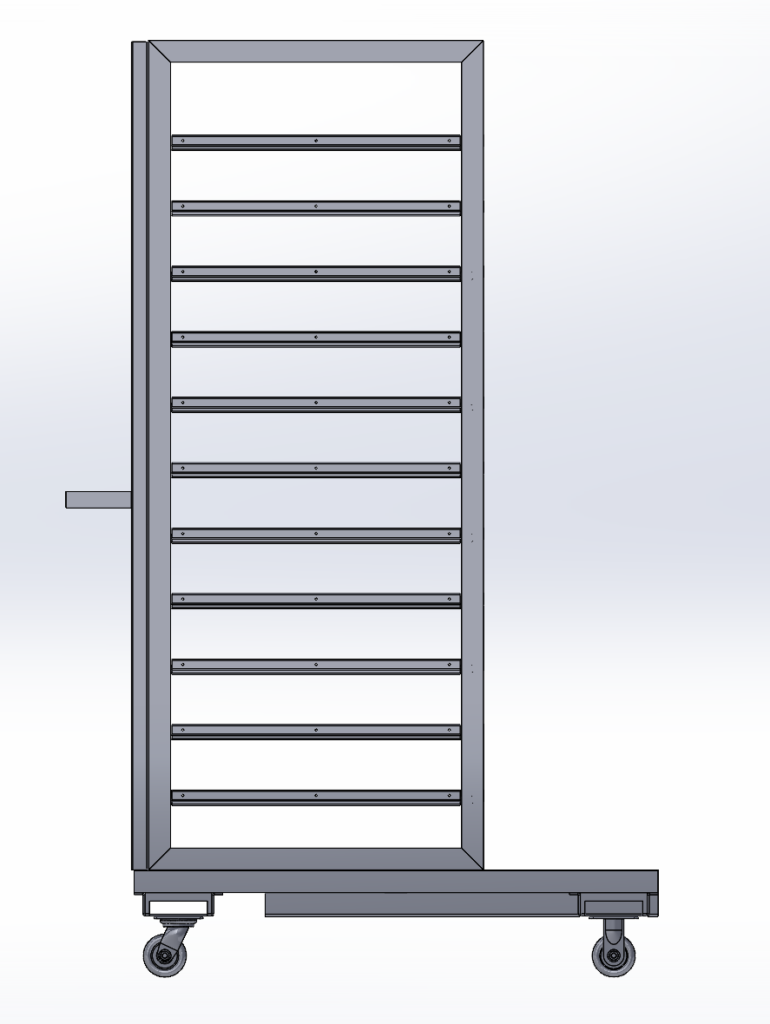

Finding ways to save space and reduce the footprint of work in progress is critical to any successful operation. One effective strategy is going up instead of out—which can be achieved with our stackable storage carts.

These carts not only decrease the footprint of the work in progress but also allow workers to manually roll them from one work center to another, eliminating the need for a forklift for every move.

Bonus: avoid the hidden costs of forklifts

There are tremendous hidden costs associated with forklifts that simple solutions like rolling carts can mitigate significantly.

Forklifts have steep operating expenses, for one thing, and they often must be manned by a special operator in a dedicated position. Even then, it’s not uncommon for parts to fall off the forklift pallet during transport.

Using a custom material handling solution in place of a forklift is an easy win for many warehouses.

Request a Custom Material Handling Cart from Ameritex

If you’re looking for a material handling solution, don’t settle for off-the-shelf products that never fully meet your needs. Get in touch with Ameritex, and we’ll make you a custom material handling cart for your unique application. Request a quote today.