It’s imperative to design sheet metal fabricated electrical enclosures for the right National Electrical Manufacturer Association (NEMA) protection rating to ensure that electrical components aren’t exposed to the elements.

But the fact is that any enclosure housing electrical components requires some degree of weatherproofing. Operator cabins for construction vehicles and dredging, touch-screen kiosks and outdoor vending machines, canopies over doors and porches, and outdoor storage containers are just some of the custom fabrications that need protection.

These applications aren’t electrical enclosures, per se, but customers often specify NEMA protection ratings for them—and at Ameritex, we’re committed to adhering to NEMA standards. If you aren’t sure which NEMA protection rating your enclosure needs, you’ll know by the time you’re done with this piece!

NEMA 3R vs. NEMA 4 and NEMA 4X Enclosures

Most of the requests we receive for weatherproofing these enclosures are for NEMA 3R, NEMA 4, or NEMA 4X ratings.

NEMA 4 and NEMA 4X enclosures are completely waterproof and provide significant water protection against anything from water hoses to rushing water. Common applications include oil-filled cabins and power rooms that must withstand frequent power washing. The major difference between 4 and 4X is that 4X enclosures have the added protection of being corrosion-resistant.

NEMA 3R enclosures are water-resistant and protect against falling rain. It costs significantly less to achieve a NEMA 3R rating than a NEMA 4 or 4X rating, so we recommend NEMA 3R enclosures unless waterproofing is absolutely necessary.

4 Design Secrets for Better Weatherproofing

In our experience providing sheet metal fabrication services for NEMA 3R, NEMA 4, and NEMA 4X enclosures, we’ve identified helpful tips and best practices that we want to pass on to our customers:

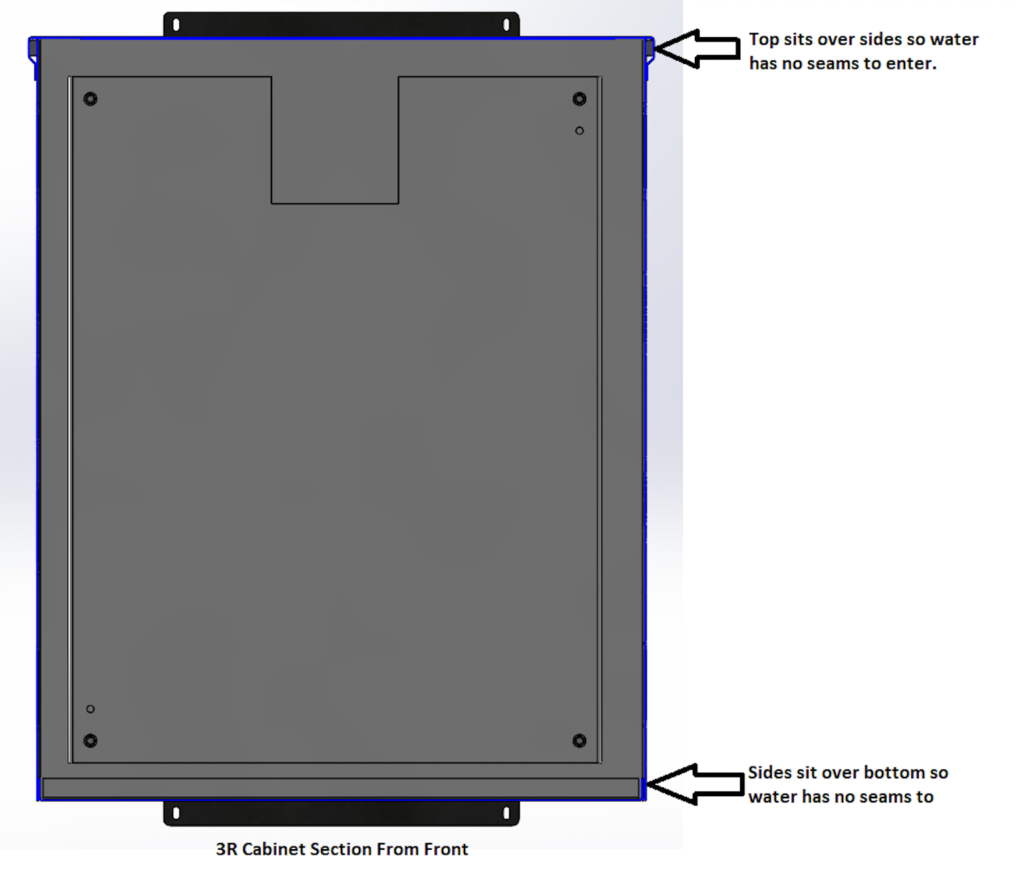

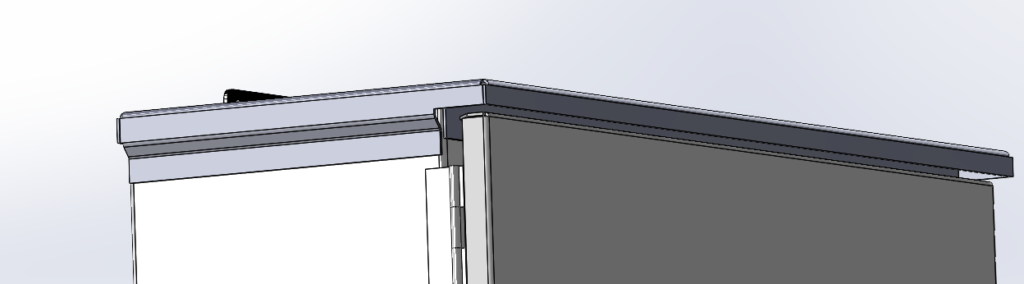

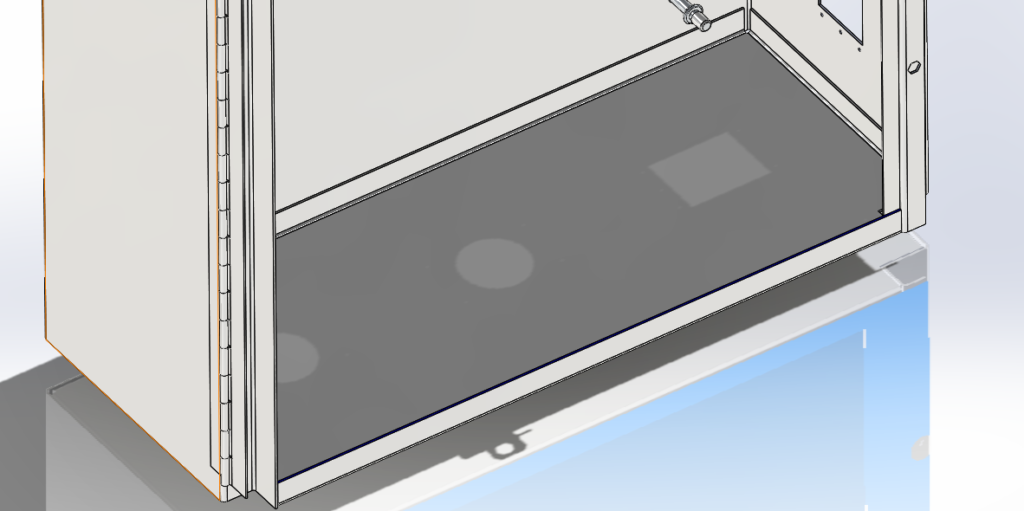

1. Design NEMA 3R enclosures to shed water

The best NEMA 3R enclosure is an intelligently designed structure whose primary purpose is to shed water. In the simplest terms, the top of the structure should sit over the sides, and the bottom of the structure should sit inside the sides. When water runs down the top, it sheds over the sides, with no cracks or seams to let it in.

2. Design gaskets in all openings of NEMA 4 and 4X enclosures

Most NEMA 4 and 4X enclosures require some type of sealant in all openings to prevent pressurized water from getting in. We recommend designing gaskets in your openings if you need to achieve one of these high ratings.

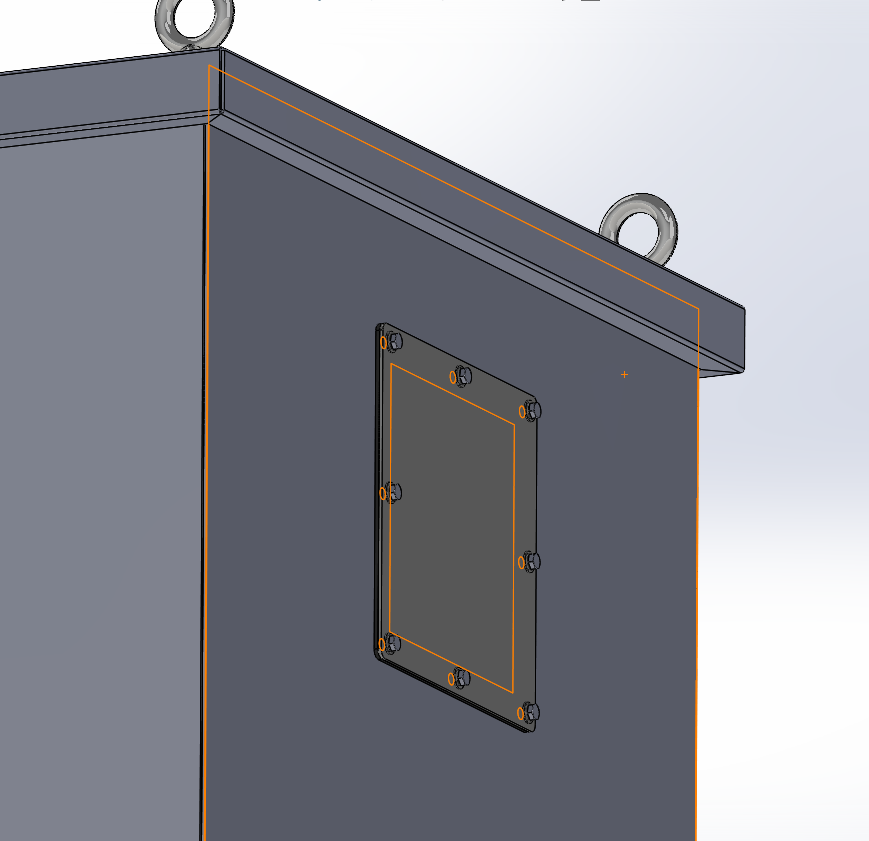

3. Design bolt hole centers strategically

When designing covers or panels that bolt on, it’s important to consider the type and frequency of hardware and the thickness of the material you’re using. If you select thin material, bolt hole centers should be designed close together to help the design properly compress a gasket and seal.

If you’re using thicker material, you can rely on the metal to hold straight when you compress it and won’t need as many bolts. With a thin piece of material, more bolts are required to prevent the material from bowing and creating a leak.

4. Identify the right latching for your enclosure

Latches are designed for specific NEMA ratings. Make sure that the latch you select for your enclosure is substantial enough to keep water out.

If you need an enclosure of any kind, you can trust Ameritex for sheet metal fabrication services. Request a quote, and we’ll jump through hoops to get your custom fabrication right.