Supplying models can be a point of frustration for many of our clients requesting sheet metal fabrication services. We get it. But as a shop that provides these services, we know there are huge benefits to using models correctly. We have a whole series of blog posts dedicated to different aspects of this topic:

- When to provide 2D vs. 3D models

- The value of 3D models in sheet metal fabrication

- How CAD files streamline sheet metal fabrication services

- How to make a model “manufacturable”

Today, we’re exploring this topic from a new angle: how to share CAD files or 3D models for sheet metal assemblies.

Sheet Metal Assembly Models 101

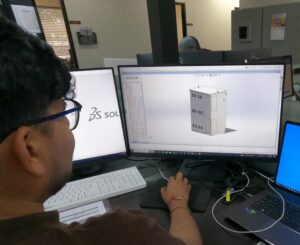

This concept can be tricky for buyers unfamiliar with CAD. In most cases, buyers default to sending an Autodesk Inventor (IAM) or SolidWorks Assembly (ASM) file. Then, we turn around and tell them we need part files or a STEP or IGES file.

Why?

Well, welcome to Sheet Metal Assembly Models 101!

The most common platforms for 3D industrial design are Soli dWorks, Inventor, CATIA, and Creo. These platforms have a similar breakdown of files: part file, drawing file, and assembly file. The different files build upon each other and can be relatively useless when they are not all accessible from the same place.

dWorks, Inventor, CATIA, and Creo. These platforms have a similar breakdown of files: part file, drawing file, and assembly file. The different files build upon each other and can be relatively useless when they are not all accessible from the same place.

For example, if you provide an assembly file without part files, the assembly will have nothing to reference when it opens. It will error out until you supply the parts it is attempting to reference. The same goes for drawing files. If you try to open a drawing file without the part or assembly it is referencing, it will error out.

So, how do you solve this problem?

3 Ways to Share 3D Models for Sheet Metal Assemblies

Here are three common ways to share files for sheet metal assemblies.

1. If you have a smaller assembly…

For smaller sheet metal assemblies, simply selecting all the part files visible in your assembly’s bill of materials (BOM) is sufficient. Be sure to reference your drawing. If there are 15 parts in the BOM, you’ll need to send us 15 part files plus the assembly file so we can open the assembly properly.

2. If your design needs some work to prepare it for manufacturing…

Have your engineer “pack and go” the assembly. “Pack and go” is a common feature in most modeling platforms. The engineer can open the assembly, click “pack and go,” and the software will automatically consolidate all the parts, drawings, and assemblies into a single zip file for sharing. This feature is the best way to share models because it allows us to modify and update drawings easily if needed.

3. If your design is ready for manufacturing…

Use standardized model formats such as STEP, IGES, or STL files. These files were designed to consolidate and share models from one software to the next. They are popular options for sharing an assembly primarily because of the reduction in file quantities and size.

A single STEP file can replace hundreds of individual files by consolidating them into one sharable file. However, there is a catch: these standardized files lose the editable features that the engineer added, which can make it difficult for your sheet metal fabrication partner to make modifications and adjustments. If you have questions about how to share your models, please reach out, and we will be glad to help. If you’re ready to move your project forward, request a quote for our sheet metal fabrication services.