With surging inflation causing prices to soar across nearly every industry, we’re fully aware that many customers who request metal fabrication services are operating within tight financial constraints.

We want to help you get the parts you need for a price that works for you. While we can’t control the bigger factors at play here, we can use our sheet metal fabrication expertise to provide cost-saving tips for parts requiring specific processes.

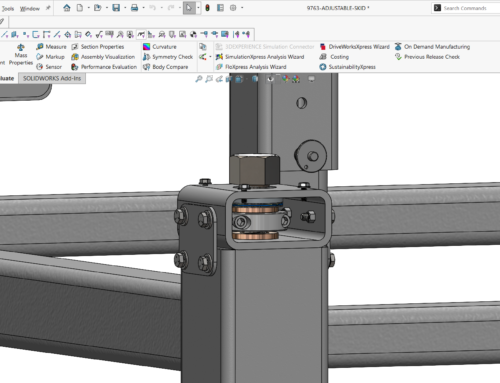

Laser Cutting Services

Setup time is one of the major factors affecting cost in manufacturing. As a general rule of thumb, parts requiring minimal operator involvement cost less.

The best way to avoid lengthy setups for laser cutting services is to keep intricate cuts to a minimum. The most cost-effective designs have features that are at least 50% of the material thickness in size with tolerances no smaller than 0.005” for a sheet of material measuring up to ¼” thick or 0.01” for a sheet of material measuring ⅜” thick and more.

Sheet Metal Bending Services

When designing a bent part, avoid overly complex bends to prevent tolerances from stacking up during metal fabrication services.

Parts with bends that need to be gauged from other bends are challenging to fabricate, and a significant level of skill is required to ensure that the part isn’t gradually thrown out of tolerance. In some cases, operators will need to start with a setup part that they can scrap to figure out how to fabricate the part perfectly, adding more cost to a project.

To save money on your bent part, begin by designing it in the simplest way possible. Aim to provide tolerances ranging from 0.015”-0.03” for 10 gauge and thinner materials and tolerances of at least 1/16” for bending thicker plate.

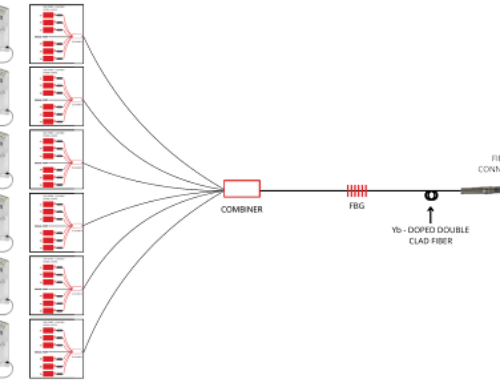

Coating Services

If you need coating services for your custom fabrication, powder coating is a much more cost-effective solution than wet paint—especially for small or low-volume parts. Often, the amount of wet paint we would need to buy to coat these parts can cost more than the parts themselves.

Powder coating not only costs less but also offers the benefits of exceptional durability and a quick turnaround time. We provide this service in-house using our incredible new powder coating system.

Select a standard and readily available color from our downloadable powder coat color chart resource to keep powder coating as cost-effective as possible.

Note: there is one exception to this coating services tip! If you have large parts measuring over 4’ x 8’, wet paint may be the better option. We make this determination on a case-by-case basis.

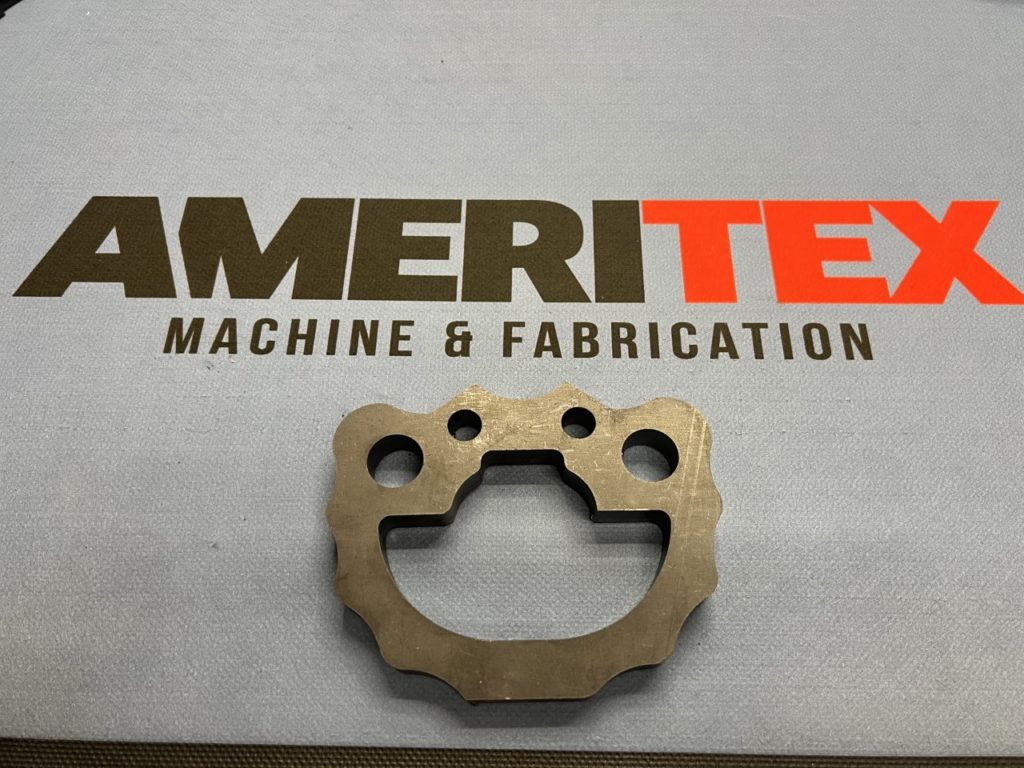

Use These Tips to Save Money on High-Quality Custom Fabrications at Ameritex

At Ameritex, we strive to make sourcing custom fabrications the easiest part of your day—and that means helping you save money when your budget is tight. If you have a project you would like to discuss, reach out for a design consultation or request a quote.