Fiber laser cutting stands out for its exceptional precision, speed, and versatility. At Ameritex, we understand that delivering the highest quality products is essential to your success, which is why we continually invest in state-of-the-art technologies like fiber laser optics. By leveraging this advanced technology, we can provide you with superior solutions tailored to your unique needs. Let’s explore how fiber laser cutting works, its advantages over other laser cutting methods, and how it can enhance your custom fabrication projects.

How Does Fiber Laser Cutting Work?

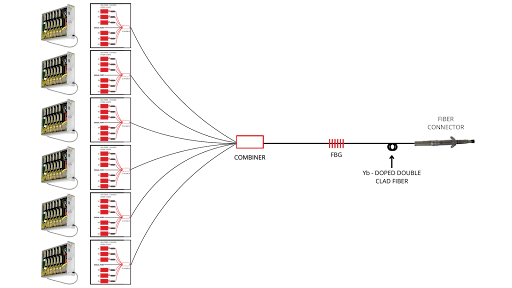

Fiber lasers are highly concentrated beams of invisible light that cut through materials with incredible precision. The process involves diodes that pump light into a fiber optic cable, amplifying it through rare earth elements. This amplification results in a powerful, efficient laser beam that can easily penetrate various materials.

A key innovation in fiber laser technology is Fiber Bragg Grating, which consists of small etchings within the fiber optic cable. These etchings manipulate light by reflecting and refracting it, enhancing the laser’s energy efficiency. The cutting process is further directed through a series of lenses and mirrors in the cutting head, allowing for precise control over the cutting parameters.

One of the standout features of fiber lasers is their flexibility. Operators can easily adjust parameters such as focus distance and standoff speed, making it possible to work with various materials. For example, cutting 5083 aluminum, commonly used in aircraft, can be challenging due to its reflective nature. However, with fiber laser technology, we can achieve clean cuts with minimal effort by fine-tuning these parameters. This adaptability allows us to meet the unique needs of each customer with precision.

5 Key Advantages of Fiber Laser Cutting

Fiber laser cutters offer a range of benefits that help us deliver high-quality results for your custom fabrication needs:

- Speed and Efficiency: Fiber lasers are significantly faster than CO2 lasers, especially when cutting thinner materials. In fact, fiber lasers can be up to 40% faster when working with the same materials. This increased speed translates into shorter lead times and faster project turnarounds, helping you meet tight deadlines without sacrificing quality.

- Versatility Across Materials: One of the biggest limitations of CO2 lasers is their difficulty in cutting highly reflective materials like aluminum and stainless steel. Fiber lasers, on the other hand, can handle a broader range of materials, including reflective metals. This versatility allows us to take on various projects, from industrial applications to intricate designs, ensuring we can meet your specific requirements.

- Lower Maintenance, More Uptime: CO2 lasers require regular maintenance because their focusing mirrors come into direct contact with the environment. A dirty or misaligned mirror can affect cut quality, necessitating time-consuming recalibrations. In contrast, fiber lasers feature protective window glass that shields the focusing lens, reducing maintenance needs and ensuring that production runs smoothly with minimal downtime.

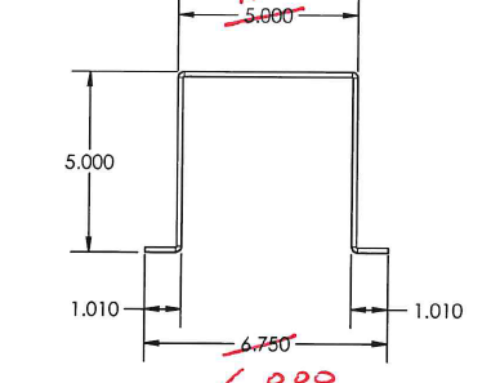

- Smoother Surface Finishes: The precision of fiber lasers results in smoother, cleaner cuts, which means less post-processing is required. This reduction in secondary operations, such as grinding or deburring, saves time and lowers overall production costs. The superior surface finish provided by fiber lasers is particularly beneficial for projects requiring high accuracy and aesthetic quality, such as custom doors, electrical enclosures, and switchgear panels.

- Cost-Effectiveness: With faster cutting speeds, reduced maintenance requirements, and fewer post-processing steps, fiber laser cutting technology contributes to lower overall project costs. This cost-effectiveness allows us to offer competitive pricing without compromising quality, ensuring you receive the best value for your investment.

Ameritex’s Commitment to Excellence

At Ameritex, we’re dedicated to leveraging the latest technology to provide superior quality in custom metal fabrication. Our investment in fiber laser cutting technology allows us to enhance our capabilities, streamline our processes, and meet the diverse needs of our customers.

Whether you’re looking for a custom door, a complex metal part, or a high-precision enclosure, our experienced team is equipped with the knowledge and tools to turn your vision into reality. Our commitment to excellence means that we prioritize your satisfaction at every stage of production, ensuring that your project is completed on time and to your exact specifications.

Ready to Experience the Benefits?

If you have a project that needs laser cutting, Ameritex is here to help. Our advanced fiber laser technology, combined with our skilled team, enables us to deliver precise, high-quality results tailored to your needs. Contact us today to request a quote, and let’s get started on your next project. Experience the Ameritex difference and see how our commitment to innovation can elevate your custom metal fabrication projects.