In custom metal fabrication, laser cutting technologies stand out for their precision, efficiency, and versatility in handling a wide variety of materials. Two of the most widely used laser cutting technologies in metal fabrication are fiber lasers and plasma lasers. While both technologies offer unique advantages, selecting the right one for a specific job can significantly impact the final product’s cost and turnaround time.

How do Fiber Lasers and Plasma Lasers Differ?

Fiber lasers and plasma lasers represent two distinct approaches to cutting metal, each with its strengths. Understanding these differences is key to choosing the right tool for any given project.

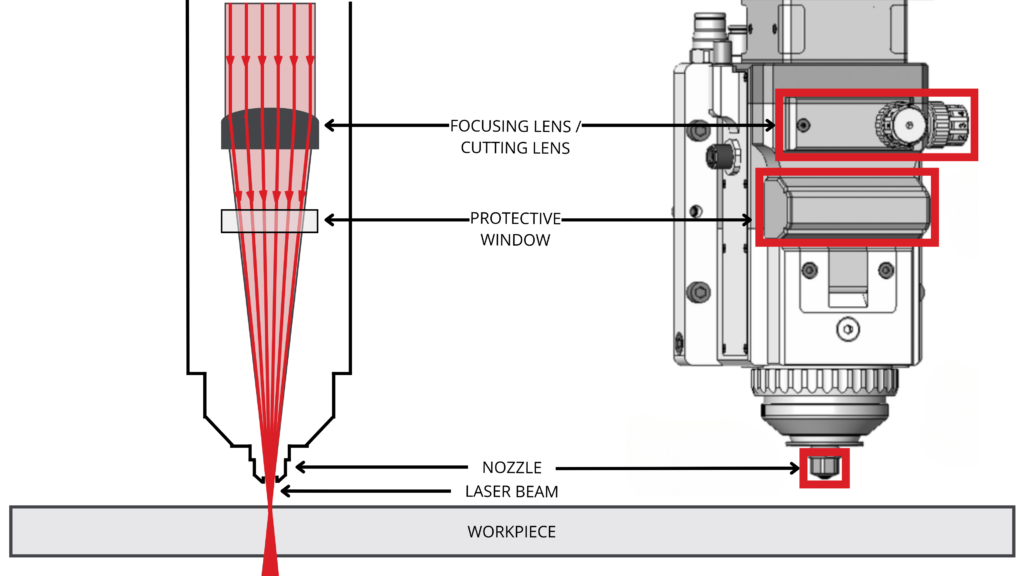

Fiber Laser: A fiber laser is a type of solid-state laser that uses fiber optics to generate and deliver a high-powered laser beam. The core of this technology is a glass fiber that is coated and used to amplify light. The laser beam travels through the fiber, which focuses it onto the workpiece, resulting in an extremely precise and powerful cutting tool. Fiber lasers are renowned for their ability to cut a wide variety of materials and thicknesses with exceptional accuracy. The precision of fiber lasers often leads to smoother edges on the cut material, reducing the need for additional finishing processes like grinding or polishing.

Plasma Laser: On the other hand, a plasma laser operates by creating a high-velocity jet of ionized gas, or plasma, which is used to cut through metal. While plasma lasers are effective in cutting thicker materials, they tend to offer lower precision compared to fiber lasers. The edges produced by plasma cutting are generally rougher, which may require more finishing work to achieve the desired smoothness.

At Ameritex, we recognize the importance of both technologies in metal fabrication. While fiber lasers are our go-to choice for most applications due to their precision and efficiency, we still utilize plasma lasers for specific tasks. For instance, plasma lasers are particularly useful for making small cuts or working with thicker materials.

Choosing the Right Laser for the Job

When it comes to selecting the appropriate laser for a metal fabrication project, several factors need to be considered, including the material type, thickness, desired precision, and overall project requirements. At Ameritex, we are experts in laser cutting. Our expertise in both fiber and plasma laser technologies allows us to choose the best tool for the job, ensuring that our customers receive the highest quality results.

Fiber lasers are among the most advanced cutting machines available today, offering unparalleled precision and speed. These lasers are capable of cutting intricate designs with tight tolerances, making them ideal for applications in industries such as aerospace, medical device manufacturing, and electronics. The high precision of fiber lasers ensures that even the most complex designs can be executed with accuracy, reducing the need for additional processing or finishing work. At Ameritex, we have four fiber lasers: two tube cutting lasers (BLM) and two flat bed lasers (LVD).

One significant advantage of fiber lasers is their cutting speed. Fiber lasers can cut through materials much faster than plasma lasers. Additionally, fiber lasers have fewer moving parts compared to plasma lasers, which translates to less downtime and lower maintenance costs. The reduced need for post-processing, such as grinding or polishing, also contributes to lower costs and faster lead times for our customers.

However, there are situations where plasma lasers are the preferred tool. For example, when working with thicker materials, such as those commonly used in construction applications, plasma lasers offer the necessary power to cut through the material effectively. While the edges may require more finishing work compared to those produced by fiber lasers, the ability to handle thick materials makes plasma lasers indispensable for certain tasks.

Your Trusted Experts for Laser Cutting Services

In custom metal fabrication, the choice between fiber lasers and plasma lasers is not a matter of one being superior to the other; rather, it depends on the specific requirements of the job. Fiber lasers excel in precision, speed, and efficiency, making them ideal for intricate designs and applications where accuracy is paramount. Plasma lasers, while less precise, are better suited for cutting thicker materials.

At Ameritex, our deep expertise in both fiber and plasma laser technologies allows us to choose the right tool for every project. By leveraging the strengths of each laser type, we ensure that our clients receive the best possible results, whether it’s for a highly detailed aerospace component or a heavy-duty construction part. Our commitment to quality, precision, and customer satisfaction makes us a leader in the metal fabrication industry, capable of tackling any challenge with the right technology and expertise.

If you have a project that involves metal cutting, request a quote today!