In manufacturing, rework refers to the need to modify or correct parts that have already been produced, and it can have far-reaching consequences for a project. From extended lead times that delay production schedules to increased costs that strain budgets, the pitfalls of rework are numerous and impactful. We aim to shed light on the primary causes of rework and how it can be effectively avoided through collaboration in the early stages of a project.

Primary Causes of Rework

Rework can occur for several reasons, each with its own set of challenges and implications:

Design Changes After Order Placement

One of the most common causes of rework is when a design is changed after an order has been placed. Even minor adjustments can require significant modifications to the already-produced sheet metal fabrications, leading to increased costs and delays.

Design Issues

What looks good on paper or works in a computer simulation may not always translate perfectly to the physical world. Sometimes, unforeseen issues arise during the production phase that necessitate modifications to the original design.

Modifications or Change Orders

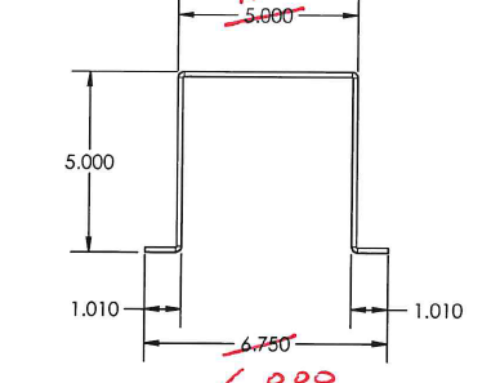

Not all rework involves complete overhauls. Often, it can be as simple as increasing the dimensions of an enclosure by an inch in every direction. While these changes might seem minor, they still require time and resources to implement.

How to Avoid Rework

How to Avoid Rework

Avoiding rework requires proactive measures and effective communication during the early stages of a project. Here are some strategies to help minimize the need for rework:

Thorough Initial Design Review

One of the best ways to prevent rework is to spend more time upfront considering how subcomponents will interact and fit together. Double-checking prints and files before submitting them can prevent many issues down the line.

Leverage Our Expertise

At Ameritex, we have deep expertise in the full process from design to manufacturing. By working closely with us from the outset, customers can benefit from our insights and suggestions. We can advise on potential design improvements that might mitigate the need for rework later on.

Provide Additional Context

Ameritex has established extensive security measures to ensure confidentiality, so you can rest assured that all proprietary information will remain confidential. With that being said, the more we know about how a part will be used, the better we can suggest design changes to enhance its performance and durability. When manufacturing a part, it’s important to consider the requirements of that part as well as the requirements of the environment in which it will ultimately be used. For example, if we know a part will be placed next to a vibrating generator, we might recommend adding some additional allowances to account for the vibration.

Ingenuity in Design

One of the keys to avoiding rework is embracing ingenuity and flexibility in design. At Ameritex, we pride ourselves on our ability to think creatively and offer innovative solutions. Here are a few ways we bring ingenuity into the design process:

Keeping an Open Mind

There are often multiple ways to manufacture a part. For example, a design might call for an open box made from four welded sheets. However, using forming operations to create the box from a single sheet can reduce the amount of welding required, saving time and costs. Being open to alternative manufacturing methods can lead to more efficient and cost-effective solutions.

Dialogue and Collaboration

We encourage customers to involve us during the engineering and design phases. At Ameritex, we have capabilities, equipment, and expertise including our engineering services that many other custom metal fabricators do not. This collaborative approach allows us to leverage our unique equipment and expertise to find the best possible solutions.

Design for Manufacturability

Our team can provide valuable input on design for manufacturability, ensuring that parts are designed in a way that makes them easier and more cost-effective to produce. This could involve advice on material selection, welding callouts, finishing choices, setting the right tolerances, and more.

The Leader in Custom Metal Fabrication

Ameritex offers unparalleled service in the metal fabrication industry, and the key to our success is our collaborative approach to working with our customers. Whether you’re looking for tube laser cutting and bending, custom sheet metal enclosure fabrication, large-scale sheet metal assembly, or any one of the many services we offer, we’ve got you covered!

Request a quote today and let us know how we can help with the design and fabrication of your next product.