At Ameritex, quality assurance is more than just a series of procedures; it is a fundamental mindset ingrained in every aspect of our operations. For us, quality assurance means ensuring that our customers receive products that meet the highest standards of precision and reliability.

Our commitment to quality begins at the moment a request for quote is received and extends through every stage of production until the final product is shipped. Our rigorous approach to quality assurance and the measures we take ensure that our products meet and exceed our customers’ expectations.

Setting a High Bar

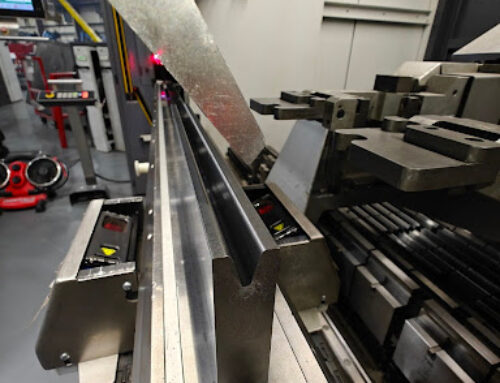

At Ameritex, we believe that quality is the responsibility of every team member at every stage of the process. Our philosophy is simple: if you are not dedicated to making the best possible sheet metal fabricated products, you cannot expect to have happy customers.

Quality starts during the quoting process. Our sales and engineering teams work closely with customers to understand the critical aspects of each product. This detailed communication ensures that we know exactly what is required, which in turn ensures that our customers receive precisely what they need and expect.

We employ a robust documentation process and multiple checks at every stage of production. Quality assurance is not a single final check but a comprehensive in-process evaluation. Every quality check verifies that each preceding step has been completed correctly, with no pending non-conformance reports (NCRs) or discrepancies. Every component must have material traceability reports, welding certifications, weld maps, and all necessary documentation signed off by the responsible employees before it can be shipped.

Quality Tests We Perform

To maintain our high standards, Ameritex utilizes a variety of rigorous quality tests. Here are some of the key tests we perform:

Magnetic Particle Testing

Magnetic Particle Testing

Magnetic Particle Testing (MT) is crucial for inspecting heavy lifting points on fabricated skids that support large modular energy buildings. These structures, often measuring between 30 to 60 feet in length and 14 feet in height, require reliable and robust components. MT helps us detect surface and subsurface discontinuities in ferromagnetic materials, ensuring the integrity and safety of these critical lifting points.

Leak Testing

Leak testing is essential for any components that hold liquids, such as drip pans or oil catch vats on generators. We use Dye Penetrant Testing to meticulously examine the external surfaces of welds and ensure there are no leaks. This process involves applying a penetrant fluid to the surface, which seeps into any flaws. After wiping away the excess penetrant, a developer is applied. This developer draws the penetrant out of the defects, making them visible under proper lighting conditions. This test is particularly effective for identifying fine cracks that might not be visible to the naked eye.

UL & NEMA Rating

We have recently introduced UL rating for our vessels, including pressure and hydrostatic testing. These tests ensure that our pressure vessels can withstand the required pressures without any risk of failure. By adhering to UL standards, we provide an additional layer of confidence in the safety and reliability of our products.

Load Capacity and Pull Strength Testing

While we can perform a variety of load capacity and pull strength tests in-house, for components requiring testing beyond 10,000 lbs/sq inch, we outsource our testing to specialized facilities. These tests are vital for ensuring that our products can handle the demanding loads they will encounter in their operational environments. By verifying the load capacity and pull strength, we confirm that our products meet the stringent requirements of their intended applications.

ISO 9001 Certification

Ameritex is proud to be an ISO 9001 certified facility. This certification reflects our commitment to maintaining a comprehensive quality management system. Achieving ISO 9001 certification involves implementing a series of checks and balances throughout the manufacturing process. Every department is held accountable for their part in the process, ensuring that any non-conformances are documented, traced back to their root cause, and analyzed to prevent recurrence.

Periodic audits by external auditors ensure that we consistently adhere to the ISO 9001 standards. These audits verify that we are hitting all the key points of our process. The certification not only demonstrates our dedication to quality but also provides our customers with the assurance that they are receiving products manufactured to the highest standards.

Quality at the Forefront of Fabrication

At Ameritex, quality assurance is not just a process; it is a core value that drives everything we do. From initial sales to final shipment, we are committed to delivering products that meet the highest standards of quality and reliability. Through rigorous testing, meticulous documentation, and a company-wide dedication to excellence, we ensure that our customers receive the exceptional products they deserve.

We are the leading provider of precision sheet metal fabrication services, covering all of your metal fabrication needs including tube bending services, powder coating services, custom steel structure fabrication, and more.

Request a quote today to experience quality without compromise!