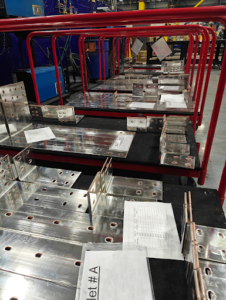

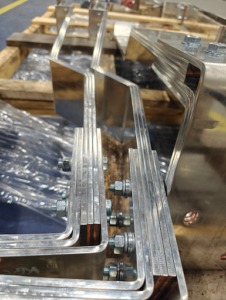

Many customers trust Ameritex to fabricate busbars, contactors, and other sheet metal parts made from copper, a material known for its high thermal and electrical conductivity.

We’re so committed to providing copper fabrication services that we recently invested in two new machines that we reserve explicitly for the popular material. That means there’s no risk of particulates from harder, ferrous metals attaching to the equipment tooling and impacting the quality of the softer, non-ferrous copper workpieces.

Here, we’re spotlighting one of these machines: the Euromac Digibend 800 CNC press brake for sheet metal bending.

Benefits of the Euromac Digibend 800 CNC Press Brake

Unlike most traditional press brakes, which are vertical, the Digibend offers horizontal bending on a flat bed, providing distinct advantages for busbars and other copper parts.

Extreme precision

Extreme precision results from laying the part on a flat surface instead of referencing against two small fingers. The machine’s design allows for precise, clean bends with minimal marks or indents, allowing the current in a busbar to flow seamlessly for optimal conductivity.

Intricate geometries

The ability to bend the intricate geometries common in busbars potentially reduces the need for welding and enables us to save considerable time. We can even bend a closed shape like a square with this machine!

Fast tool changes

The Digibend makes changing from one standard tool setup to another fast and easy. We also have the option of creating custom tools as needed.

Efficient design and programming

Team members can design parts and features on a screen attached to the machine and run simulations on the spot.

Team members can design parts and features on a screen attached to the machine and run simulations on the spot.

Need Sheet Metal Parts Made from Copper?

If you need sheet metal parts made from copper, Ameritex has the dedicated equipment and personnel to get the job done right. We fabricate a high quantity of busbars already and can’t wait to fabricate your copper busbars, contactors, and other parts.