Lead time is a huge priority for many of our customers. Ameritex is always seeking out new ways to deliver precision sheet metal fabrications at record speeds—like with our new CADMAN software that helps us automate processes.

During the quoting process, our customers often ask us for quick tips on how to get their parts back faster. We thought it would be helpful to compile some of this information into a list of easy design tips.

5 Easy Design Tips for Faster Custom Fabrications

Here are 5 super simple design tips for getting your next precision sheet metal fabrication faster than ever:

1. Make small cut features greater than half the material thickness.

If you need holes laser cut into your part, it’s exponentially harder for us to cut a hole that’s less than half the material thickness. A good rule of thumb is that if you have a ½” thick part, design your holes ¼” thick.

It’s possible for us to cut holes smaller than half the material thickness if that’s what your custom fabrication requires. But it will take us longer because there’s a good chance we’ll lose the cut somewhere on the sheet—especially when we’re cutting hundreds of parts.

This risk is highest when we’re working with lower-quality materials, which is increasingly common right now due to rising commodities prices.

2. Smooth out sharp corners with small arcs.

When you’re designing signage or freeform shapes, consider placing a tiny radius on your sharp points so the laser that’s cutting the piece can change directions quickly and easily.

This minor change will help us maintain an exceptional cut quality, and the small visual alteration will be virtually undetectable on the final product.

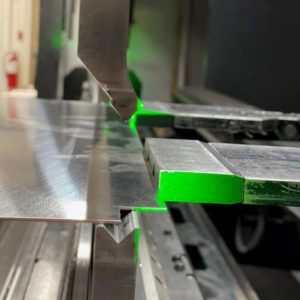

3. Design flanges long enough for the particular material thickness.

If your part requires sheet metal bending, it’s important to have enough material to reach all the way across the press brake’s v-shaped die.

The v-size is typically set to 5-8 times the thickness of the material, and the die ultimately determines how short the flanges can be. We recommend multiplying your material thickness by 8 and designing your flanges to be only about half of that measurement so that the material will reach the other side.

Since the v-die determines everything when it comes to designing features into a part, it’s also important to design holes and other features outside the die by a considerable amount.

A good rule of thumb is 1.5 times the thickness of the material plus the inside radius of the bend. This usually equates to 3 or 4 times the thickness of the material when using 5 to 8 times material thickness for die size, but will increase as the bend radius and die sizes increase.

4. Place hardware in a way that we can install it all before or after bending.

One of the things that slows us down the most on the shop floor is having to go back and forth between hardware insertion and bending. If we can place all the hardware before or after bending, we can save a ton of time on your custom fabrication.

Pressed in hardware like PEM studs in particular can be challenging, so discuss the placements with us up front. We’ll make recommendations on where to place your PEMs or when to use a different type of hardware. The easier it is for us to place the hardware, the quicker and cheaper we can get you your part.

5. Give us a place to hook your part for painting and powder coating.

Parts that don’t have any holes are difficult for us to hang for painting or powder coating.

We have workarounds like using a clamp for lightweight parts. But often we need to add time for touchup paint afterward. For heavy parts, the clamps aren’t always strong enough, so there’s a risk of the part dropping or becoming scratched.

If you know you’ll need painting or powder coating for your custom fabrication, consider strategically placing a hole cutout as small as ⅛” for us to use for hanging purposes. The hook we use will only touch the inside of the hole, which is much easier to touch up than the surface of the material.

Ready for your next custom fabrication? We strive to make sourcing your parts and products as fast and easy as possible. Get a quote today!