We’re thrilled to offer a new capability that enables us to provide high-quality welding services faster than ever before. Introducing. . . laser welding at Ameritex!

What Is Laser Welding?

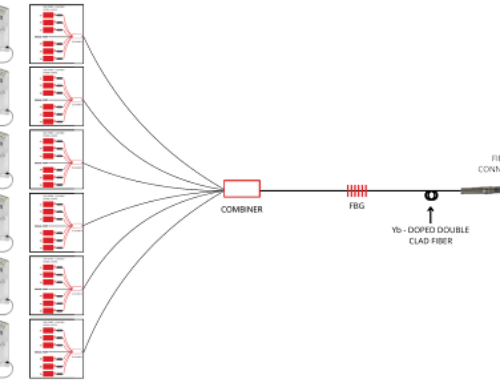

Laser welding is a quicker and easier alternative to traditional MIG and TIG welding. It uses a precisely targeted laser beam to fuse materials.

While it was traditionally reserved for light-duty applications, laser welding has become much more versatile due to recent technological advancements. In addition to fusing metals, laser welding can use wire feeders to add filler material for a stronger weld.

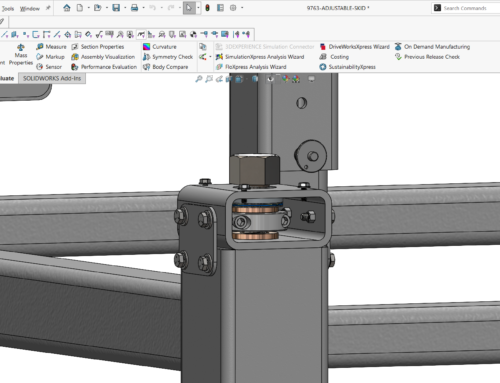

We invested in an IPG Lightweld laser welding system and have been using it to optimize customers’ custom metal fab projects—particularly those with thin and highly precise aluminum parts—with great success.

Whether a part requires spot welding, stitch welding, or seam welding, this convenient little machine can get the job done quickly and flawlessly.

7 Benefits of Laser Welding

Here are several of the benefits of laser welding compared to traditional MIG and TIG welding:

- Small heat-affected zone. TIG welding has always been the go-to technique for thin and precise custom fabrications, but it’s a slow process and generates high levels of heat, resulting in distortion. The heat-affected zone for laser welding is much smaller, significantly reducing the risk of distortion.

- Unparalleled speed. Laser welding is 4x faster than TIG welding, allowing us to turn welded parts around much more quickly.

- Easy to use. Highly skilled MIG and TIG welders are precious resources at many precision sheet metal fabrication shops. Laser welding is easier to learn and perform than traditional welding—all one needs is a steady hand to deliver consistent results. With this capability available to us, we can allocate internal resources more effectively to deliver parts quickly.

- Safe for reflective materials. Unlike CO2 lasers, fiber lasers are safe to use on reflective materials like aluminum. The fiber laser’s frequency is high enough to penetrate the material instead of reflecting off of it.

- Low risk of weld defects. Weld defects like undercuts (grooves on the base of the metal) and burn-through (open holes in the metal) are common with MIG and TIG welding—but not with laser welding. This innovative technique provides smooth and consistent welds every time.

- Minimal part setups and post-processing. Laser welding produces such clean welds that post-processing operations like grinding or polishing are rarely necessary. Customers get their parts faster as a result.

- Compatible with dissimilar metals. Traditional welding typically involves fusing the same materials (e.g., carbon steel to carbon steel, stainless steel to stainless steel), but with laser welding, we can easily mix and match materials. For instance, we could weld a copper busbar to an aluminum battery component—no problem.

Ultimately, our new laser welding capability enables us to produce superior quality welded parts quickly while allocating our internal resources more effectively—resulting in faster lead times for our customers. We’re always looking for ways to optimize customers’ projects, so don’t be surprised if we suggest laser welding for your next custom fabrication! Request a quote today.