In recent years, CAD (computer-aided design) files have become increasingly essential to the manufacturing process, streamlining and improving everything from quoting to programming to quality control.

If you don’t provide a shop with a CAD file right off the bat, chances are they have someone behind the scenes converting your PDF into a much more useful CAD file.

Still, you may wonder, “What exactly are CAD files used for?” And we’re happy to provide the answers. Read on to learn how CAD files help us quickly transform our customers’ concepts into tangible custom fabrications during a few touchpoints in the manufacturing process.

Quoting

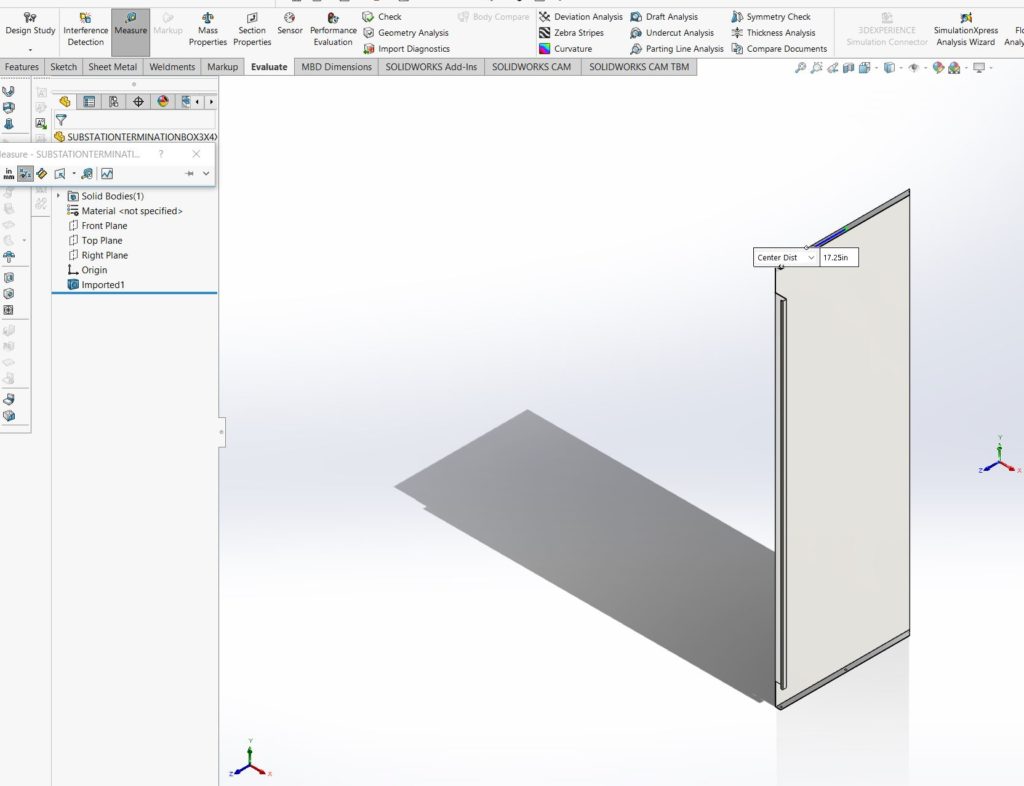

When customers request a quote from Ameritex, we ask them to provide a 3D model, which drives some of the powerful automation in our quoting platform.

The platform analyzes a model for key details, including the total linear inches of cut, number of holes, weight, countersinks, counterbores, and much more.

Using the data gathered from the model, the platform performs these critical functions:

- Plugs the variables of our choice into formulas that produce a final price

- Provides a default standard lead time based on labor hours and capabilities required

- Automatically reviews the model against Design for Manufacturing (DFM) criteria, alerting us to issues with the design that an estimator could easily overlook

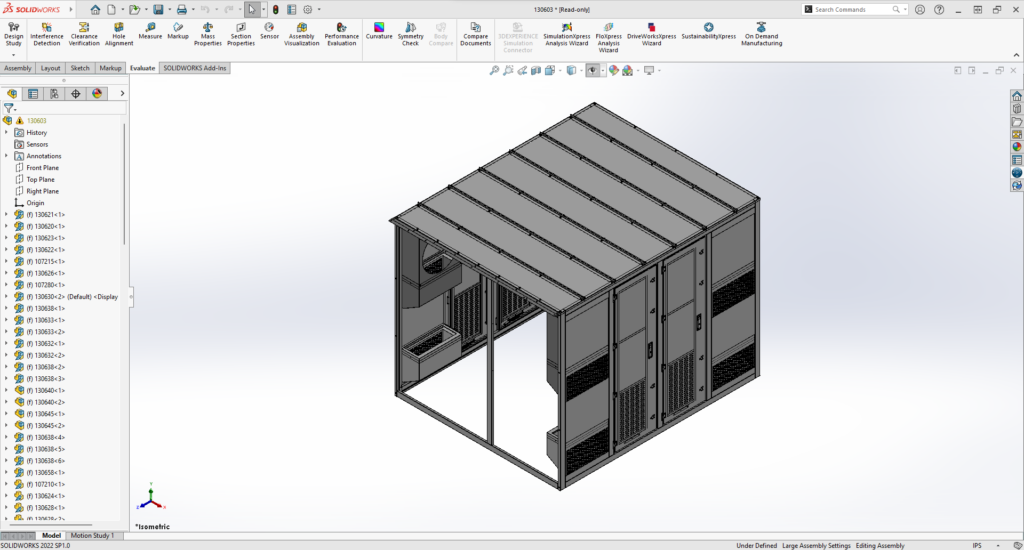

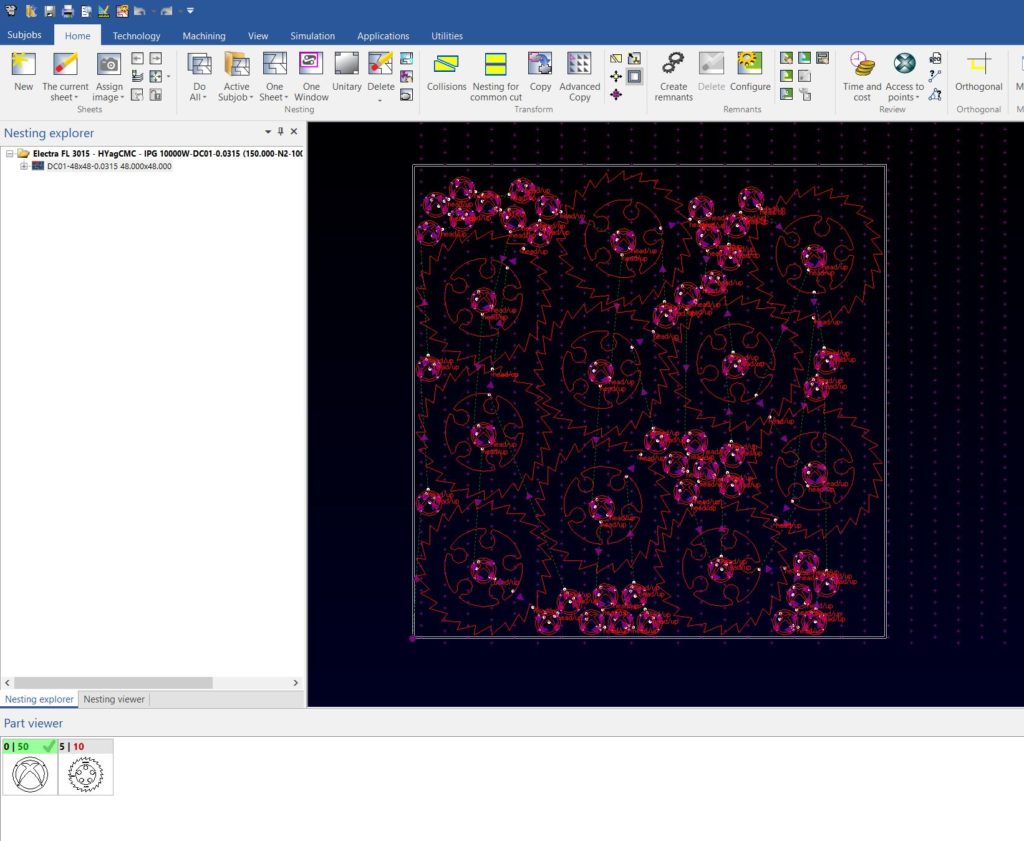

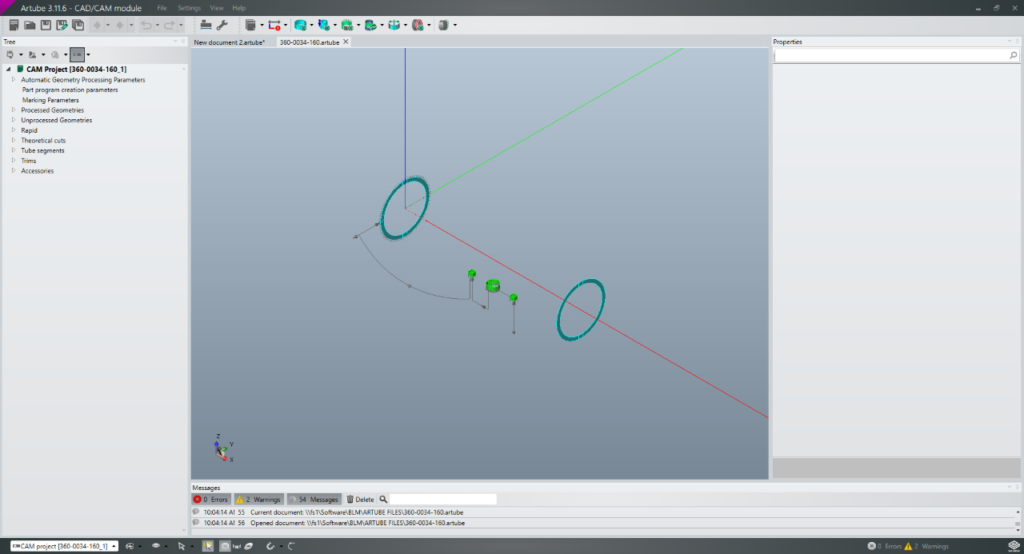

Programming

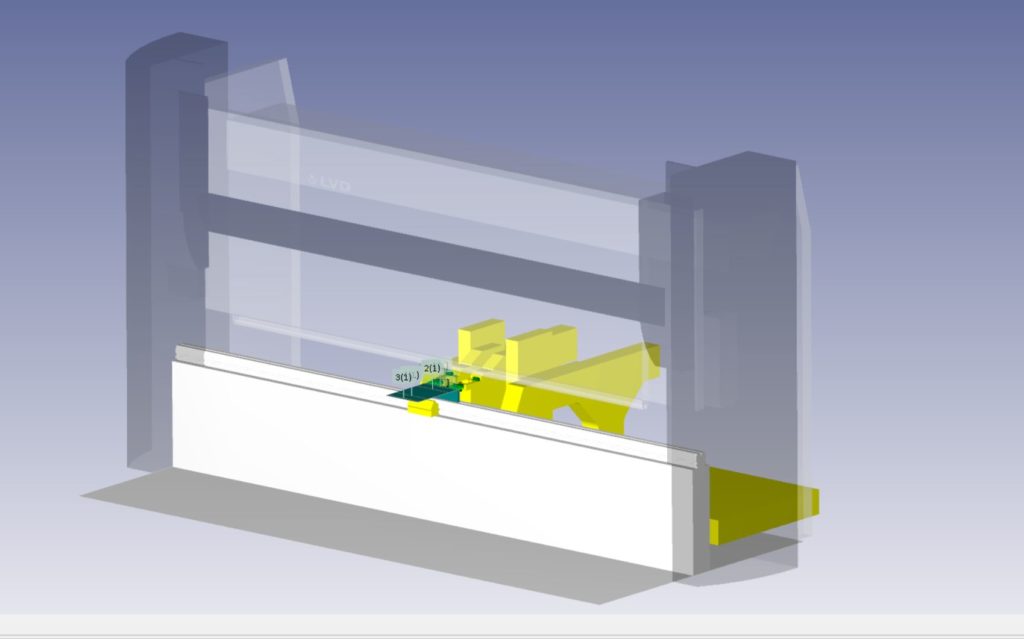

Once we receive an order, our programming team members review the 3D model and drawings provided to identify potential discrepancies. They then use the model to program the press brake and laser cutting services.

The 3D model allows them to evaluate the risk of collisions in the equipment we plan to use so that they can adjust the tooling or even take steps to modify the model if needed.

Quality Control

With the type of low-volume manufacturing standard in sheet metal fabrication, not every detail makes its way to a customer’s drawing.

When we have a customer-supplied 3D model to reference, we can keep the project moving forward in the event that the drawing is unclear or contains insufficient information.

Provide CAD Files When Requesting Metal Fabrication Services

There’s no denying that CAD files play a key role in streamlining manufacturing operations—and that role will only increase as shops of all sizes continue embracing Industry 4.0 technologies.

When possible, provide a CAD file the next time you request a quote for metal fabrication services to set your project on the right track. If you need help reviewing your design, feel free to reach out for a design consultation or submit a quote, and we’ll respond within 24 hours!