Manufacturing technology is advancing rapidly, and at Ameritex, we’re committed to incorporating the most innovative automation and artificial intelligence solutions to strengthen our metal fabrication services.

We’re excited to announce that we recently partnered with Path Robotics to provide fully autonomous welding to our customers.

Fully Autonomous Welding at Ameritex

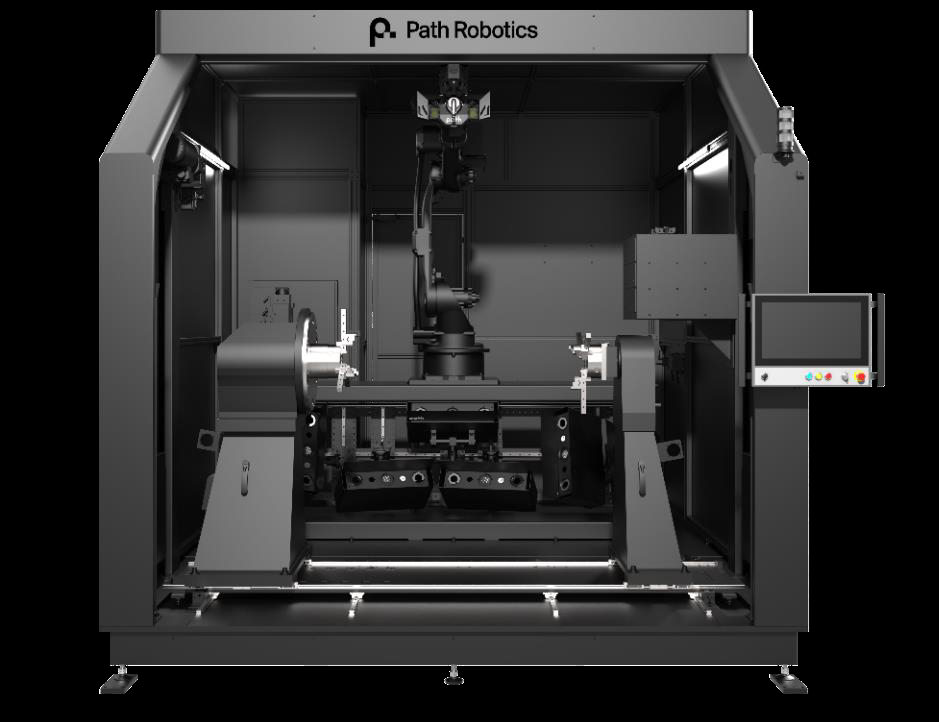

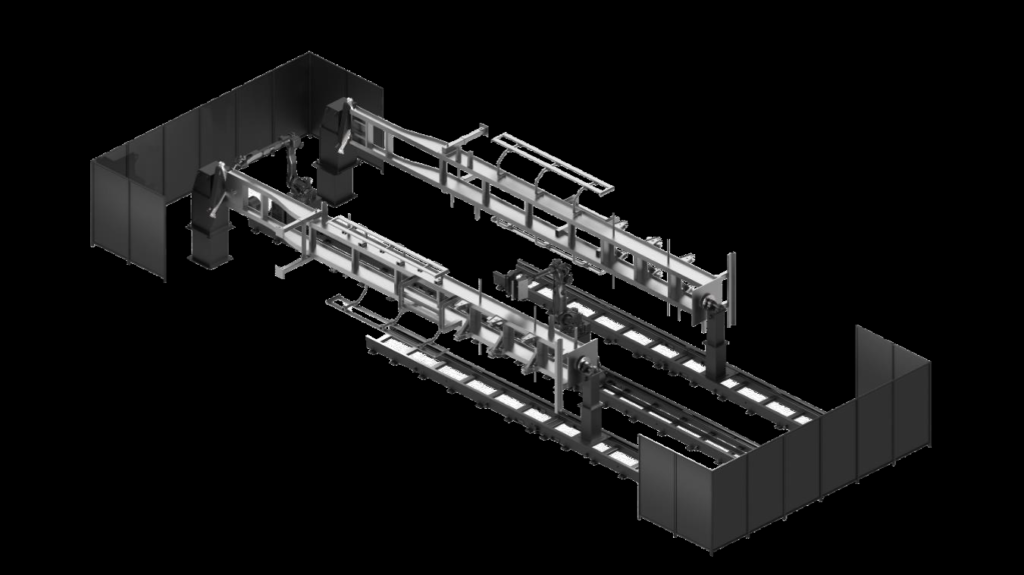

Through our partnership with Path Robotics, we’re installing a single-station AW2 welding cell and a dual-station AW3 welding cell that we plan to have fully operational by Q2 of 2023.

These innovative machines complete a 3D scan of each part as it’s placed in the cell, comparing the newly generated model to the original 3D model of the assembly to identify and compensate for any potential variations. This feature alone puts the Path system a step above other less intelligent robots that are unable to account for minor differences from one part to the next.

We’ll essentially be able to upload a 3D model, select the seams that need to be welded, and let the robot do the rest. The machine will locate features based on the model and adjust the program to accommodate any variations while also tracking the weld seams as it welds.

The AW2 cell accommodates parts up to 40” x 40” x 60”, and the AW3 cell accommodates parts up to 6’ x 6’ x 10’. Together, they’ll be able to handle about 80-90% of the welding jobs that come through our metal fabrication shop. Both machines will have automatic headstocks and tailstocks to allow for the rotation of assemblies during welding.

What Customers Can Expect from Our Partnership with Path Robotics

Every innovative solution we implement at Ameritex is for the benefit of our customers. Here’s what to expect from our partnership with Path Robotics:

- Increased capacity. The welding cells will add the equivalent of 14 welders to our capacity once the installation is complete. We’ll also be training six of our current employees to operate the equipment and keep them fed with parts 24/7.

- Faster lead times. Anytime we introduce automation into our metal fabrication services, our customers can expect faster lead times. In addition to running 24/7, the Path system is built on proprietary artificial intelligence that enables the scanners to learn as they go, getting increasingly faster with repeat parts to create efficiencies for larger orders.

- Resilience to industry challenges. As labor shortages continue to impact the manufacturing industry, automated solutions like the Path system allow us to accommodate large contracts quickly and use our internal resources more effectively.

- Latest technologies. Path Robotics will update our cells with new technologies as they become available, ensuring continuous improvements to the benefits already offered by these machines.

Did we mention that welding robots also make for a really cool shop tour? If you’re in the Conroe, Texas, area and want to stop by for a visit, let us know. Ready to get your next welding project started? Go and request a quote for our metal fabrication services.