We’re just going to say it. . . nobody likes an ugly part.

One thing that sets Ameritex apart from your typical garage shop is that we can make your custom fabrications look just as good as they function. But it’s hard to achieve a cosmetic finish when the design itself doesn’t support that goal.

In our many years of experience, we’ve identified several factors that compromise the cosmetic appearance of end products, and we’re happy to share our knowledge with you.

How to Avoid Ugly Sheet Metal Parts

Here are four simple guidelines for avoiding ugly parts when you request sheet metal fabrication services:

1. Avoid raw metal edges

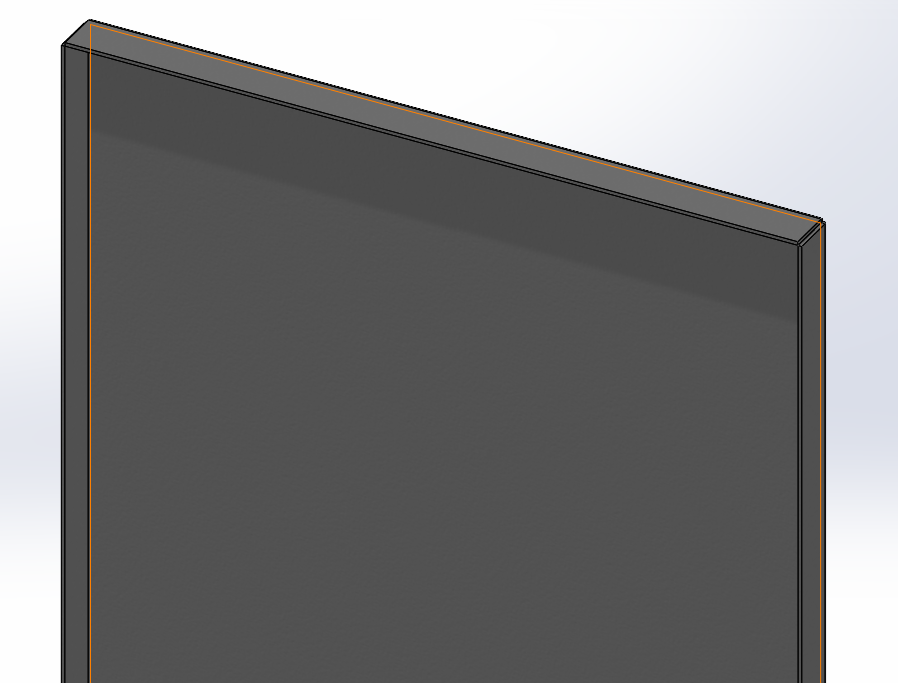

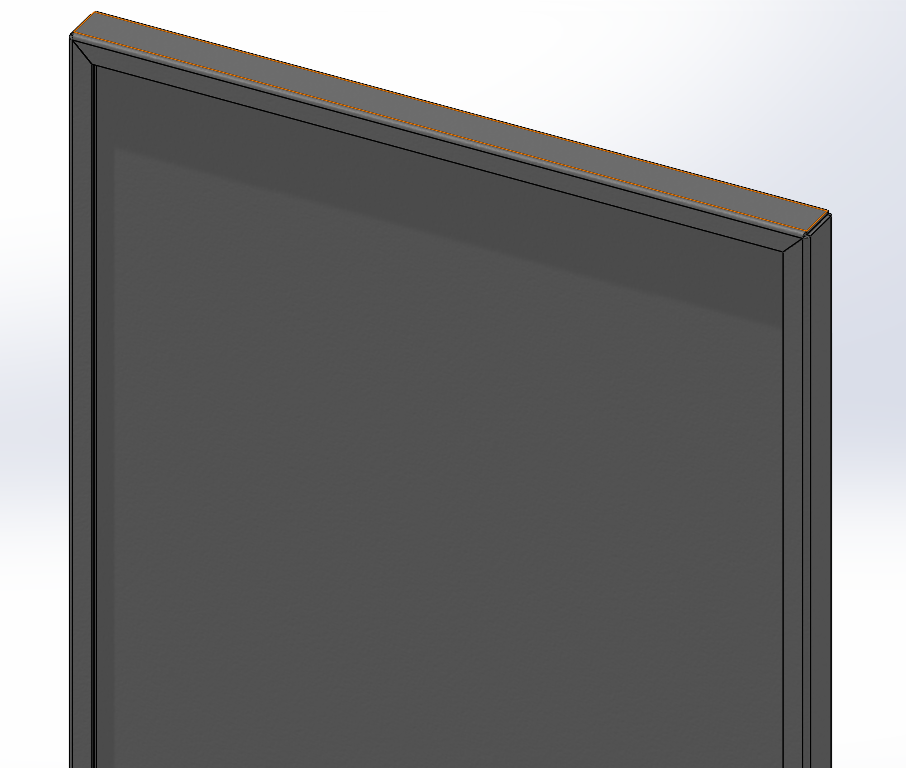

Designs with raw metal edges leave the thickness face of the material exposed to the user, which is never ideal.

For instance, a square with bends on all four sides makes a pan. If the flange you’re forming ends up visible to your product’s users, try a return or double return flange to soften the edge and ensure a more user-friendly and cosmetically appealing product.

Flat sheets that protrude from your part can easily become dented or dinged, and they’re also prone to having sharp edges that can be dangerous. To avoid flat sheets, incorporate return flanges or a hem to soften and strengthen the edges of the part. Keep in mind that a hem usually requires a tool change, so we advise using a return flange when possible, especially for low-volume part runs.

2. Avoid fully welded assemblies

Features like bolt-on doors, handles, and latches create a more professional-looking product than welding pieces together during assembly.

If your assembly combines structural frames and sheet metal parts, we recommend bolting the pieces together to create replaceable parts that can be powder coated separately. Not only does this approach allow you to easily replace parts in the event they are damaged, but it also enables your fabricator to break the unit down into pieces for better control over quality and finishing.

A coating blemish is much less expensive to repair on a small bolt-on portion of a unit than on a large welded assembly. And it’s easier for one welder to accurately fixture portions of a weldment on a table than for multiple welders to piece together and weld an entire large assembly manually. In general when you simplify the manufacturing process, fit and finish typically improve.

In fact, an assembly with bolt-on sections composed of like materials is conducive to every manufacturing process. As a general rule, keep the heavy plate and structural parts separate from the light gauge sheet metal—the materials are laser cut, welded, and powder coated differently, and separating them until assembly ensures a seamless manufacturing process.

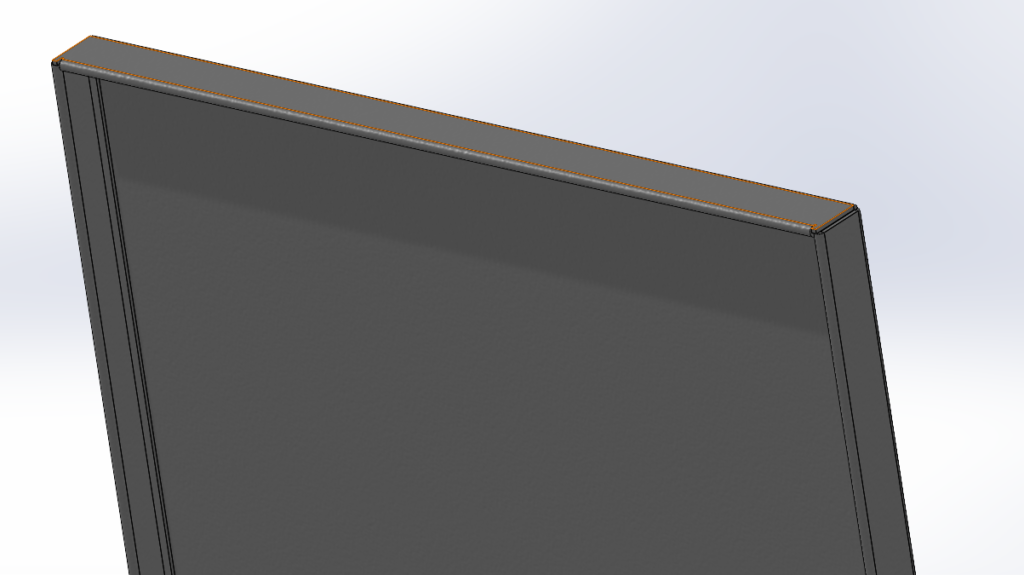

3. Avoid large expanses of flat sheet metal

No one likes a wavy or bowed surface on their enclosure, kiosk, or sheet metal weldment. Avoid this outcome by ensuring all large faces of sheet metal are reinforced in your design, especially if you need your parts welded.

Even the heat from small welds can distort a piece of sheet metal, compromising the cosmetic appearance of the end product. We recommend designing bolt-on or spot welded stiffeners in strategic locations or adding bends to your part to keep it rigid. If the part bolts to another part in the assembly, that connection can also act as a stiffener.

The optimal stiffening technique can vary significantly from one product to the next, so please reach out to us for a specific recommendation.

In general, plan to use stiffeners for areas over 4 square feet and avoid MIG and TIG welding on the open spaces of materials 16 gauge and thinner. Spot welding, rivet nuts, or pressed hardware are better alternatives for joining thinner materials.

4. Compensate for the radii of bends and structural pieces in your assembly

Finally, a guideline about what to do instead of what to avoid. 😉

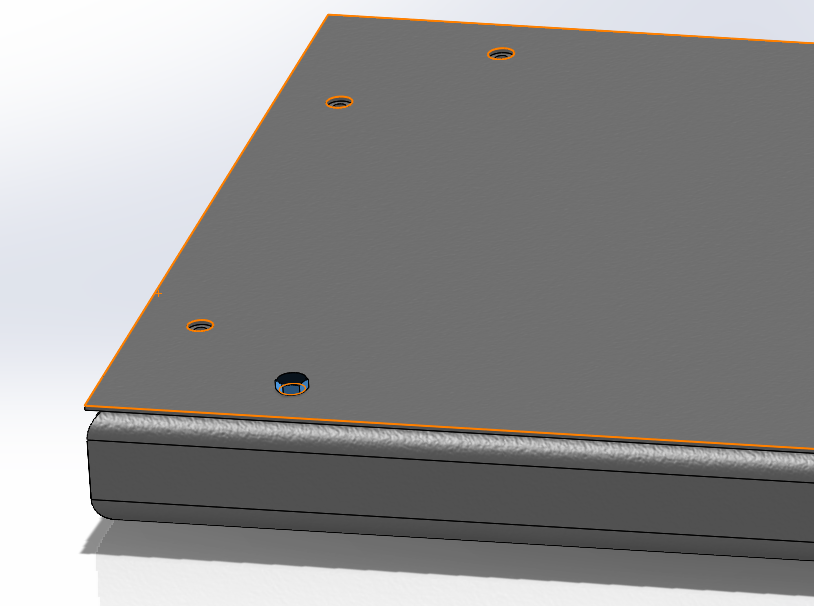

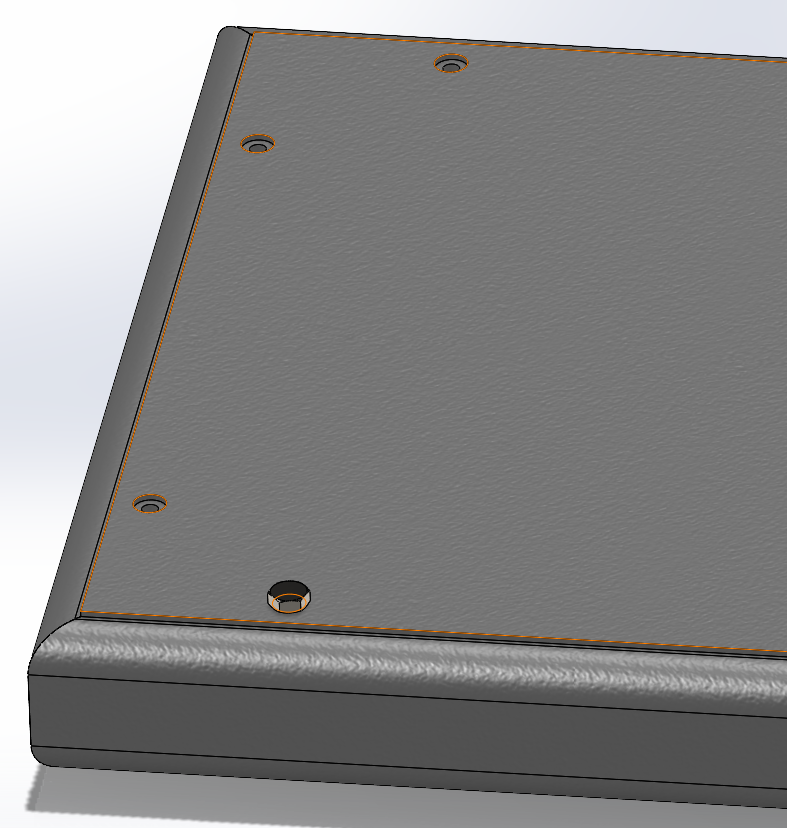

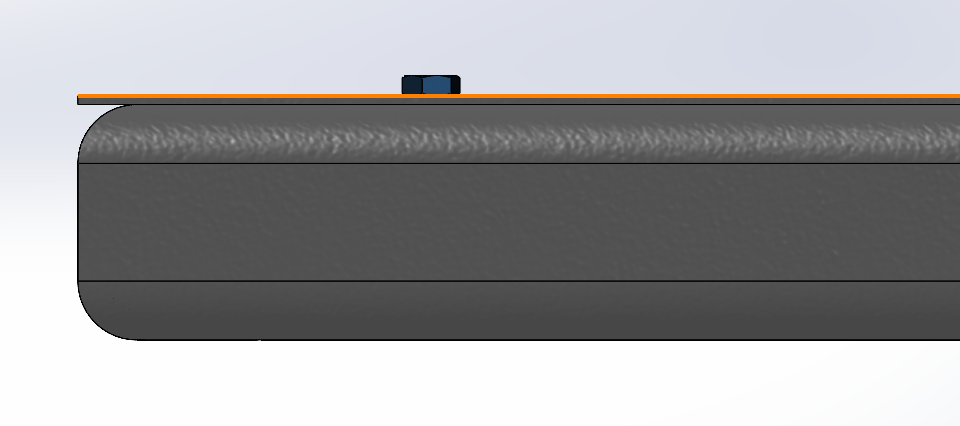

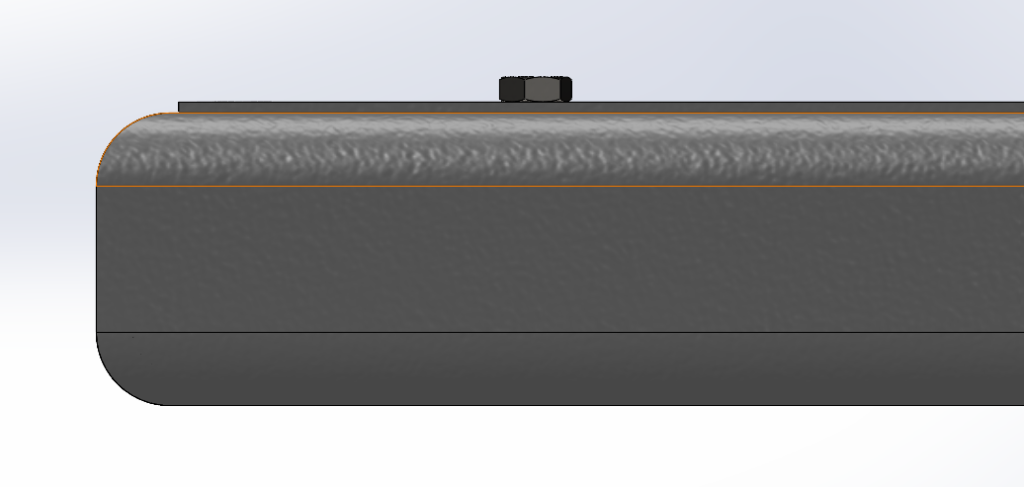

If your design includes flat sheet metal pieces welded to tubing, the flat and round edges generally won’t look good once they’ve been joined together. The same principle applies to a flat cover on the outside of a bent part. In these cases, there will be a gap where the parts meet because the bend radius and flat panel aren’t aligned correctly.

It’s possible to fix these problems on the shop floor—for example, we might cut down a side panel so that it fits nicely. But it’s never ideal to modify parts by hand that far into the manufacturing process. Instead, we recommend compensating for the radius of bends and structural pieces in your design so that all parts mate up nicely.

Why settle for ugly sheet metal parts when you don’t have to? If you need sheet metal fabrication services, Ameritex is here to build you custom fabrications with beautiful cosmetic finishes. Request a quote to work with us.