Are you overlooking opportunities to reduce cost and lead time for low-volume sheet metal parts that require bending?

One of our driving motivators at Ameritex is to get our customers their custom fabrications in record time. We often receive designs for prototype or low-volume sheet metal parts that are more complex than they need to be, which can slow down the entire sheet metal forming process and in turn drive up cost.

When you only need one or a few of a particular part, we recommend simplifying the design as much as possible.

Simplify Sheet Metal Bending to Reduce Cost and Lead Time

The next time you’re designing a low-volume part that requires sheet metal bending, keep these considerations in mind to improve cost and lead time:

Tolerances. One of the easiest ways to save money on low-volume parts is to loosen up your tolerances. Just because you can make the tolerances super tight doesn’t mean you necessarily need to for every part. Our machines can achieve tolerances of .01” in just one pass, requiring minimal setup. But when your tolerances are as tight as .003”, we have to fine-tune the machine and take multiple passes.

The more setup pieces a part requires, the higher the cost of the part. The bottom line is that if your part needs exceptionally tight tolerances, we’re more than happy to make it happen, but we don’t want our customers to spend more than what’s necessary for low-volume parts.

Part complexity. As a part becomes more complex (multiple bends, complex bending, multiple tolerances), naturally it becomes more challenging for sheet metal fabricators to bend. A part that has 6 bends with .015” tolerances can be just as difficult (or more difficult!) to work with as a part with only 1 bend and a tolerance of .003”.

When you’re designing a part with bends stacking on top of each other, be sure to determine (and clarify!) which specifications are critical. There are times when the overall length may be the only critical dimension and we’ll have some flexibility with all the little bends in between.

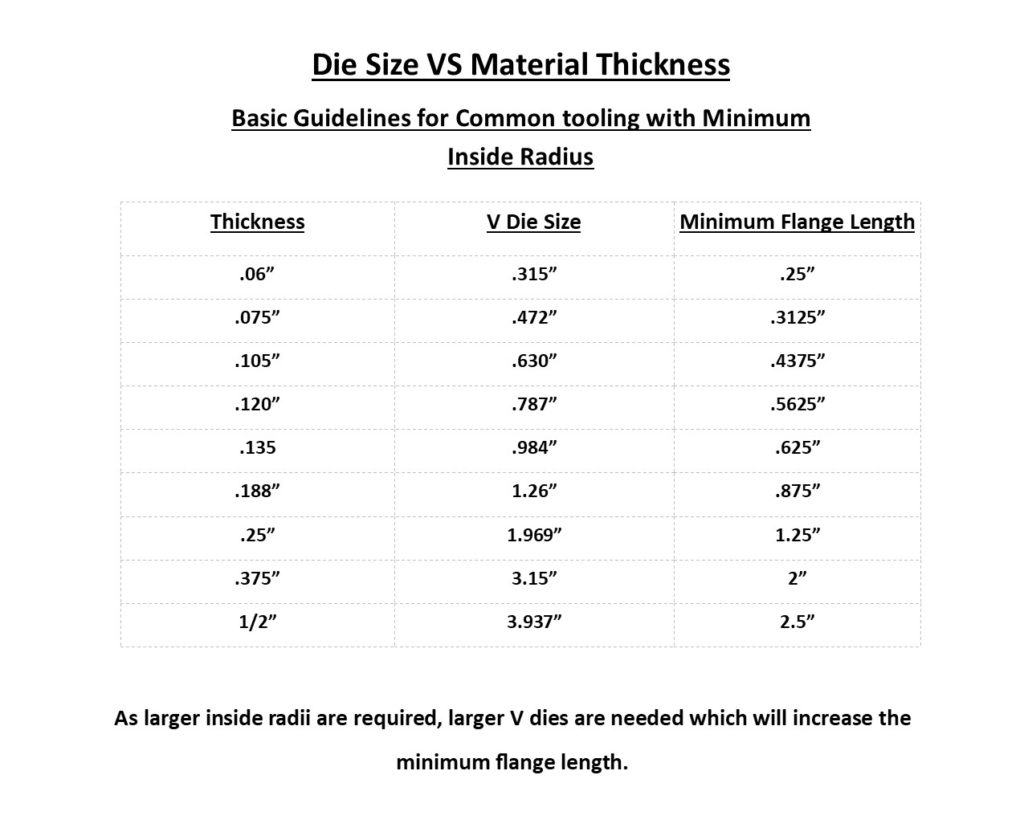

Existing Tools. Dies are expensive, so if you want to save money and lead time on low-volume parts, it’s always best to align your design around the sheet metal fabricator’s existing tools. That way you won’t have to pay extra money or wait weeks for a set of custom dies. We love hearing from customers mid-design, so don’t hesitate to call us with any questions you have about our existing tools! We also created this handy chart for your convenience:

Sometimes there’s no way around a custom tool, for low volume less critical applications making custom dies from laser cut plates could be a quick solution!

When you need precision sheet metal fabrication services, Ameritex is here to get you the parts you need in a fraction of the time. No project is too big or too small, so request a quote today, and let’s get started!