We’re thrilled to have our new LT8.20 tube laser cutter up and running for use on our customers’ latest custom fabrications.

This world-class equipment boasts incredible capabilities, including lightning fast speed, software integration, and the ability to cut structural pieces with diameters up to 9.5”. (Fun fact: we can cut profiles like angles, channels, I-beams, pipe, and custom extrusions in addition to standard tubing profiles.)

If you’re interested in tube laser cutting services for your next project, we want to make sure that you get the exact parts you need. That means not just building your part to print but also ensuring that it will function properly in its end-use application. Our goal is to save you the headache of going back and forth with us to correct a part that doesn’t function as intended.

Follow these design best practices for tube laser cutting services to get the high-quality parts you need as quickly as possible.

Design Tips for Tube Laser Cutting Services

1. Design normal cuts to optimize speed

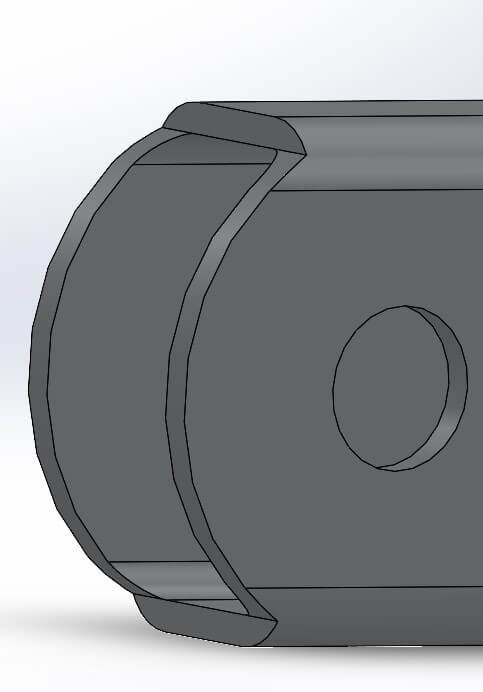

If you’ve designed parts to be cut on a saw, you’re probably accustomed to designing cuts that taper to sharp points. But achieving this type of cut on a laser cutter is a much slower cut and the quality of the cut can suffer as thickness increases.

Instead, we recommend designing what we call “normal cuts,” which are cuts that taper down to the material thickness. Normal cuts allow the laser head to remain 90 degrees to the cutting surface at all times so that as the head revolves around the part, it never tilts. For welded parts, this type of cut leaves a nice corner-to-corner fillet weld.

2. Be mindful of tolerance variations in structural materials

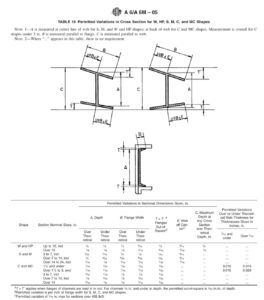

Tolerance your parts accordingly to accommodate standard raw material tolerances, which are notably larger than they are for precision sheet metal fabrication work.

The larger the diameter of the structural piece, the more likely there are to be large tolerance variations. These variations are in full compliance with ASTM standards but can pose problems if you haven’t designed your part to accommodate them. We recommend:

- Dimensioning from the centerline instead of the outside edges of structural pieces

- Referencing important holes in relation to other cut features rather than the tubing edge

- Avoiding cutouts right against the walls of the tubing unless absolutely necessary

If you’re concerned about standard raw material tolerances, let us know during the quoting process so that we can work with the material supplier directly to get you what you need.

3. Call out weld seam locations

Most closed profiles have a weld seam that must not interfere with critical features. For instance, if you’re inserting hardware into a hole, it’s important that the weld seam doesn’t obstruct the hardware.

Be sure to note the location of the weld seam on your drawing when you request tube laser cutting services. Our LT8 2.0 has built-in weld seam detection, so if we know the exact location, we can program our machine to get it right each time.

If you need tube laser cutting services, you can trust Ameritex to deliver. Request a quote to see what our new LT8 2.0 can do for you!